Carrier bands

- Home

- soluciones

- End of line

- Carrier bands

End of line

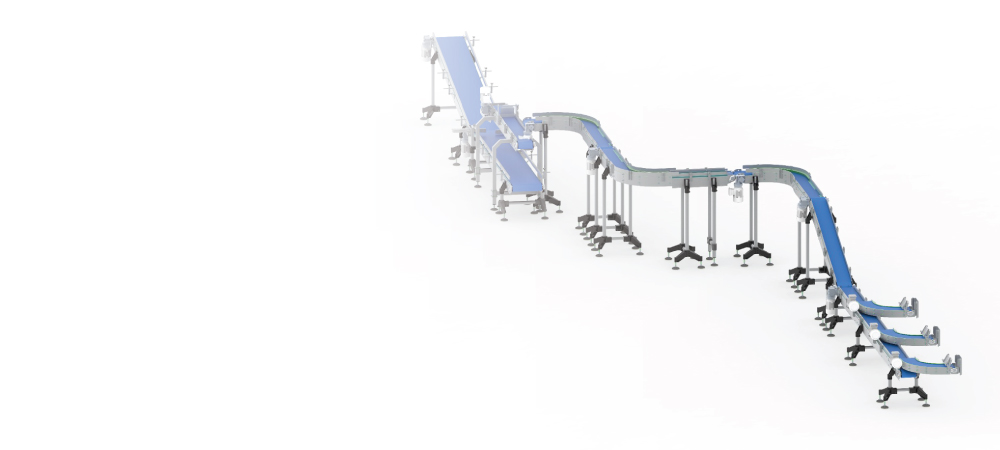

Carrier bands

Technical characteristics of the equipment

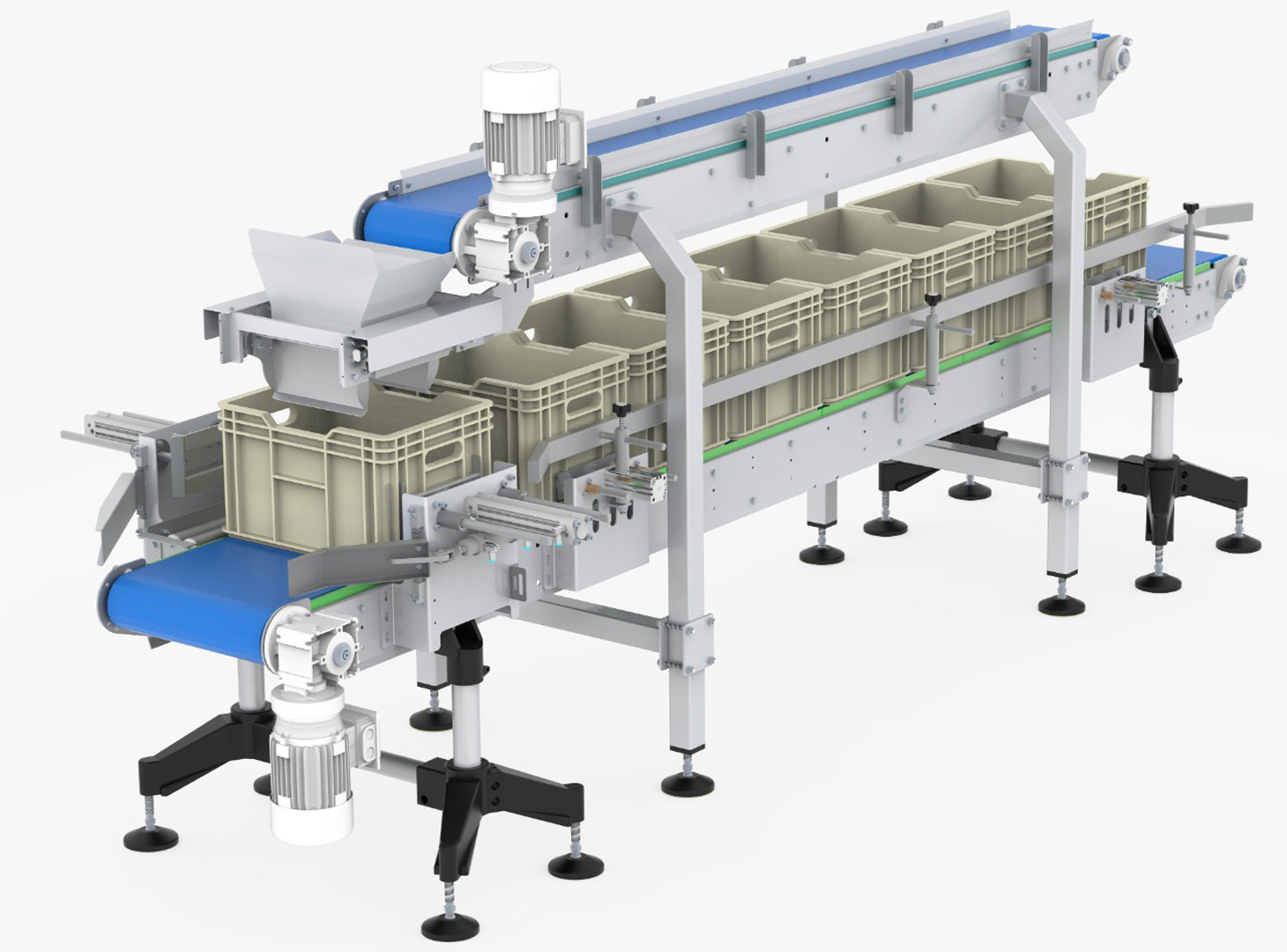

Modular system made of 304 stainless steel.

Interchangeable modules in measures from 0.3 m to 3.0 m long.

Applicable band widths from 100 mm to 1,200 mm, with links and passage from 12 mm or 1⁄2 In.

Manufacturing materials: acetal (POM), acetal LF (POM), polipropileno (PP).

FDA approval for direct contact with food.

Most relevant features

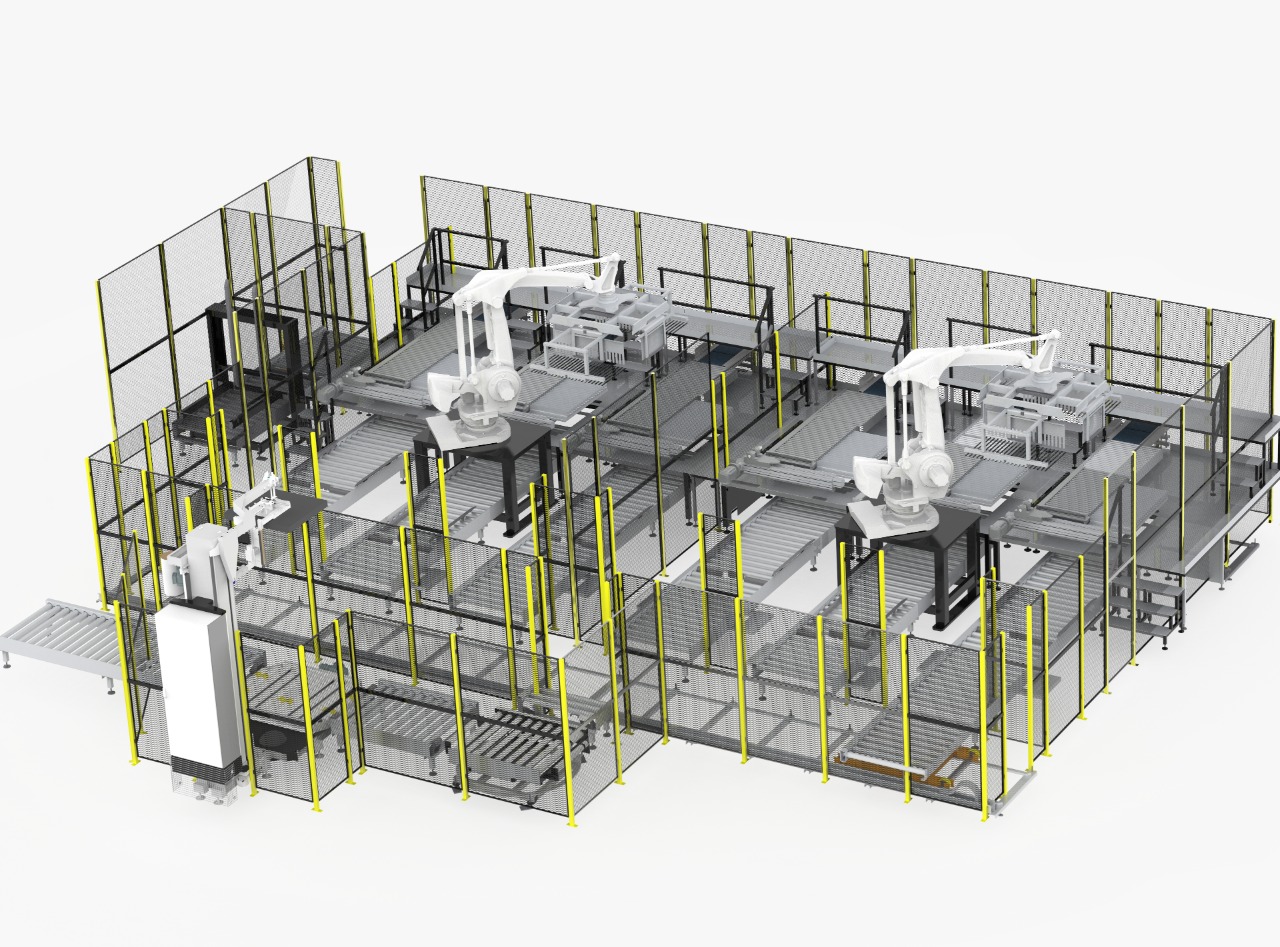

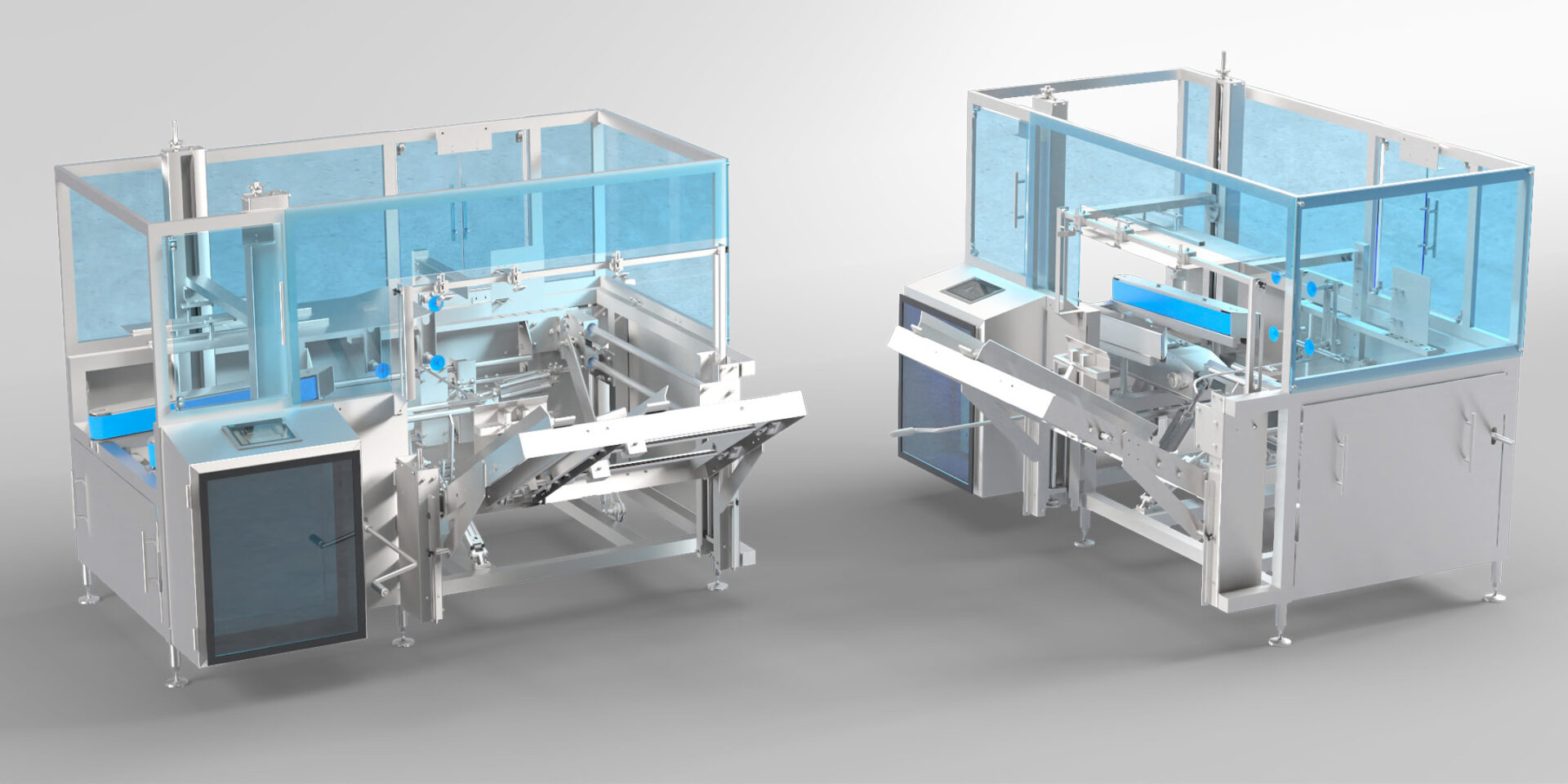

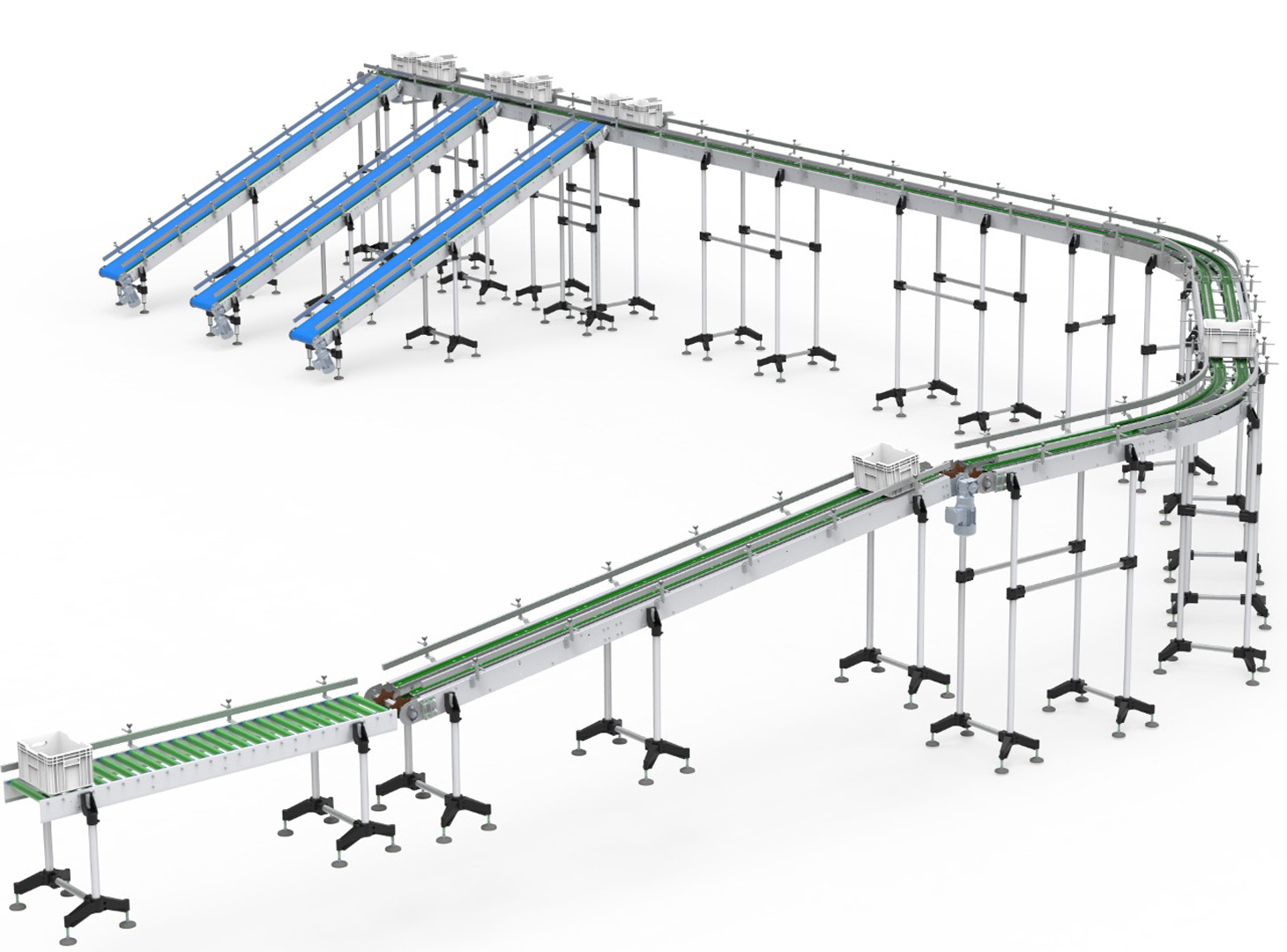

Conveyor belts are modular equipment that can be assembled according to the customer’s needs. Its design form and concept mean that they can be integrated into multiple processes in the food industry and other productive sectors.

Our modular band systems fit the handling of products that can range from 100 mm to 1,200 mm in width. The application of engineering plastics both on the wear elements or on the transport belts themselves gives the possibility of handling a wide variety of products in the food sector, maintaining aseptic standards and moving the products in a careful and controlled way.

Main benefits

- The modular band system can be adapted to the needs of each plant or production process.

- The module configuration features allow you to transport, lift, rotate and have a wide selection of flexible packaging.

- The modular band system gives the possibility of adapting different external elements such as sensors, reading devices, counting and manipulation of key conditions.

Plus differential of the conveyor belts

- The manufacturing materials of the modular bands have FDA-approved technical characteristics necessary in direct contact with food.

- Variable speed configuration according to the product or process.

Expected metrics and indicators

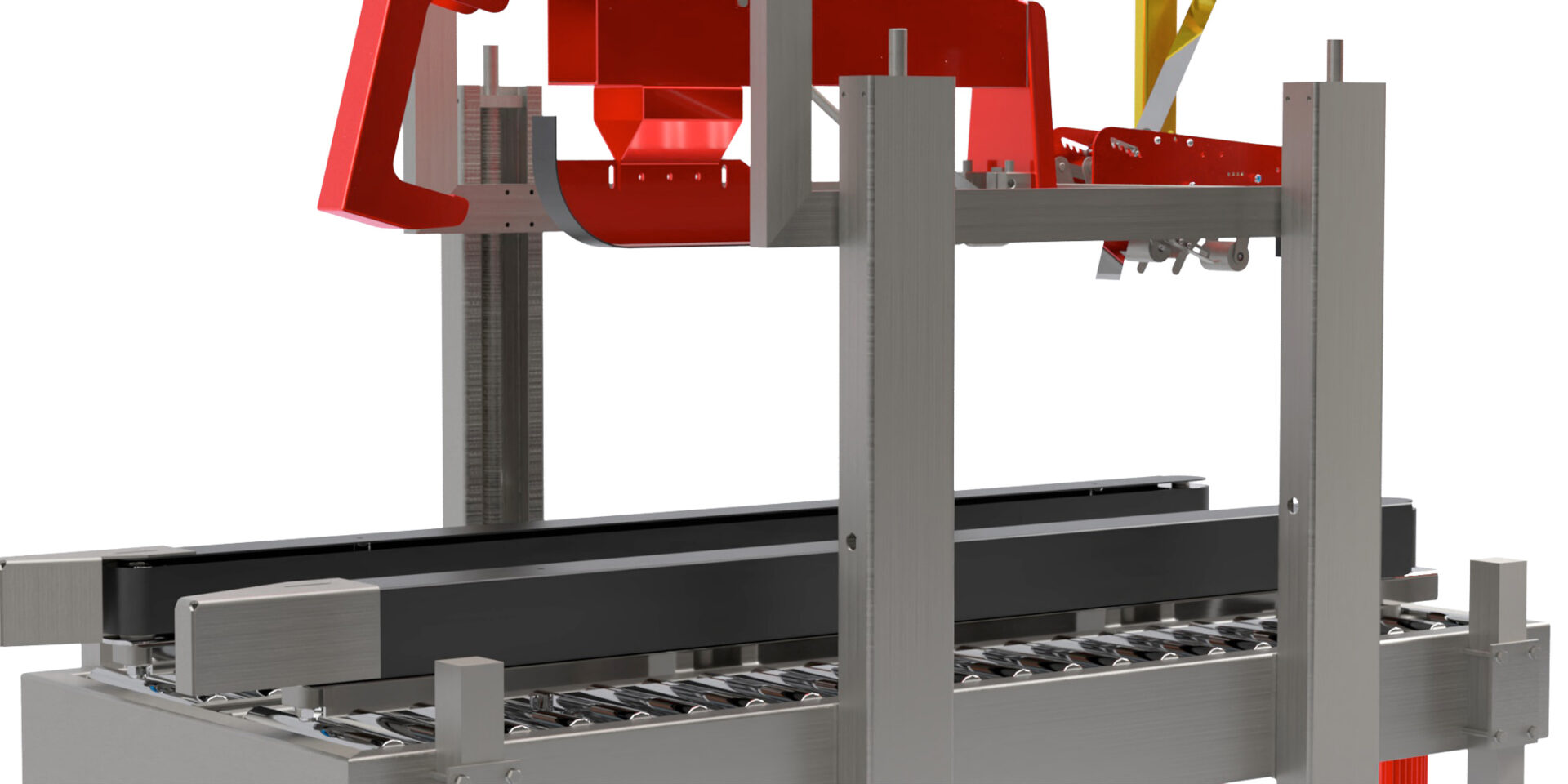

- Adaptability to spaces and production processes by moving products faster and safer.

- Modular bands manufactured under world standards of quality and safety, with great flexibility in the use of materials intended for special uses.

Manufacturing details

Equipment made of 304 stainless steel and other engineering materials, including plastics and specialized compounds suitable for contact with food that guarantee the hygiene of the process and a long service life of the equipment.

Application of different materials and modules in order to adapt and adjust the tape to processes with specific requirements.

Aspects of maintenance

All ESSI end-of-line equipment are highly functional systems that require a control and maintenance scheme to guarantee and ensure indicators of reliability, availability and production performance..

ESSI has a portfolio of services and spare parts for the timely realization of preventive and corrective maintenance. It also offers a timely remote and face-to-face technical assistance system at all times.