Bagger

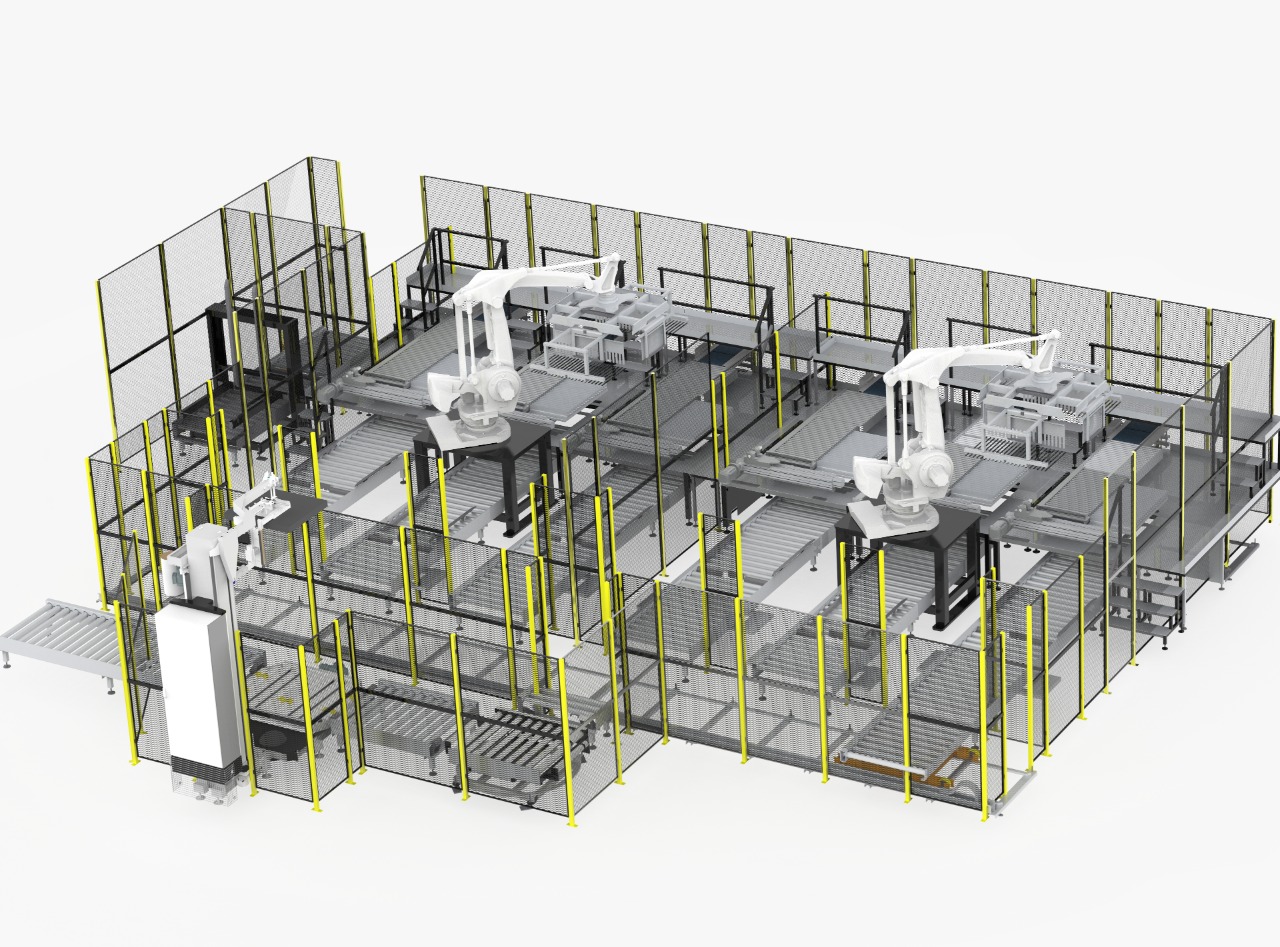

Final de línea

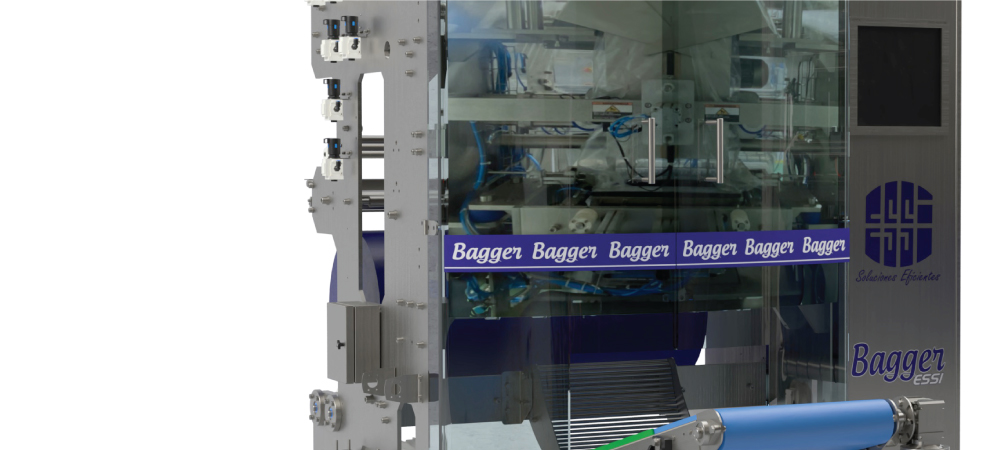

Bagger

Características técnicas del equipo

Volumen de producción: 15 fardos six pack por minuto para presentaciones de 900 ml y 1.000 ml.

Funcionalidades más relevantes

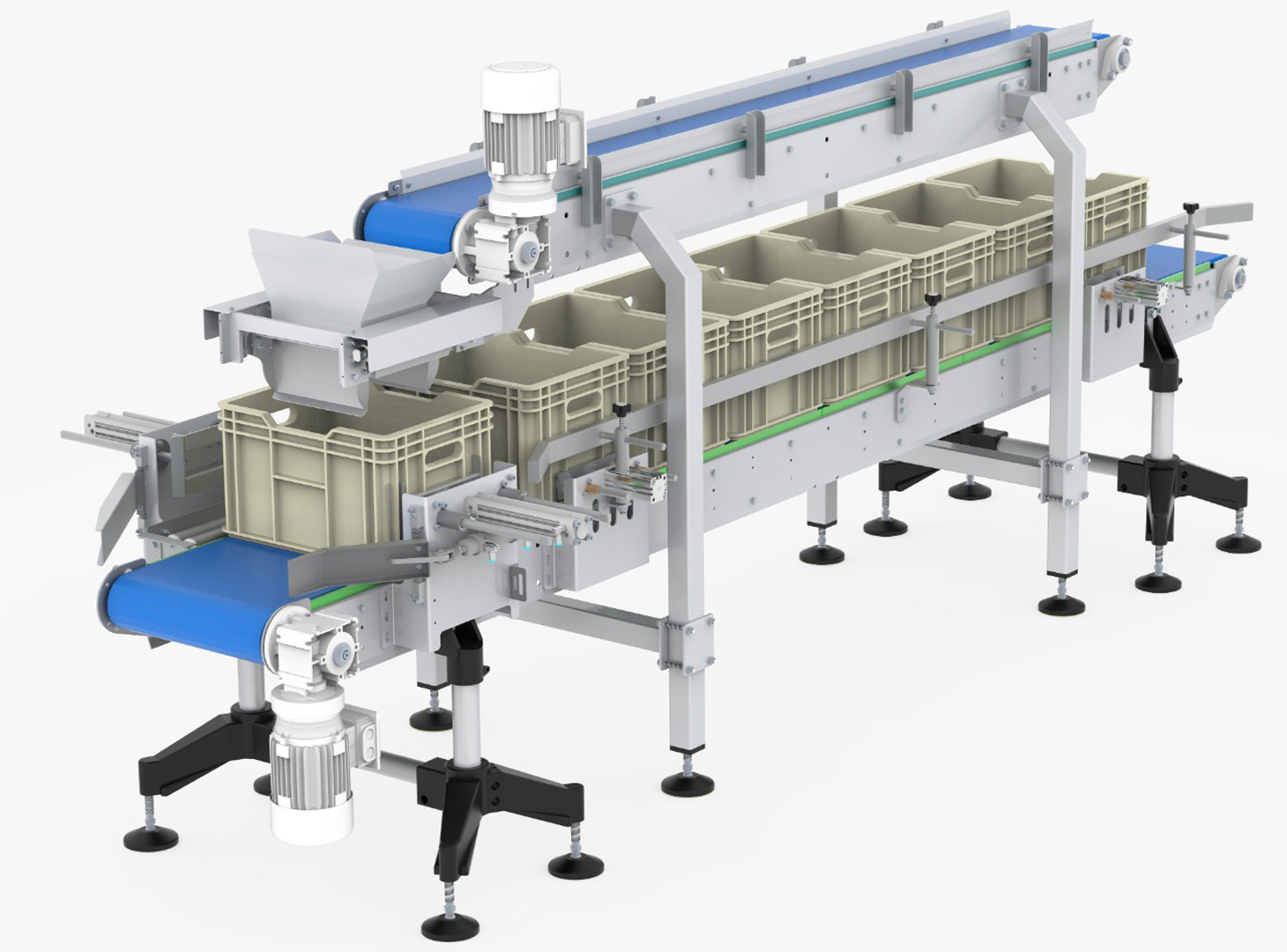

Los Bagger ESSI están diseñados para el enfardado industrial de bolsas con líquido previamente dispuestas en empaque flexible por una envasadora. El proceso de enfardado se realiza automáticamente por el Bagger con el fin de lograr un producto final con tres sellados de calidad: uno vertical y dos horizontales en presentaciones de six pack, three pack o four pack llegando hasta 5.400 u/h.

El Bagger ESSI ofrece un receptor de bolsas, controlado y dispuesto de forma vertical, en un contenedor por unidades individuales que puede configurarse para fardos de tres y seis unidades según el nicho de mercado objetivo.

Su ajuste compacto permite un posicionamiento de alta precisión, gracias a un movimiento servoasistido que, apoyado en un sistema de sensores ópticos, cuenta y relaciona la posición que debe tener la bolsa en su contenedor de acuerdo a las cantidades finales de entrega.

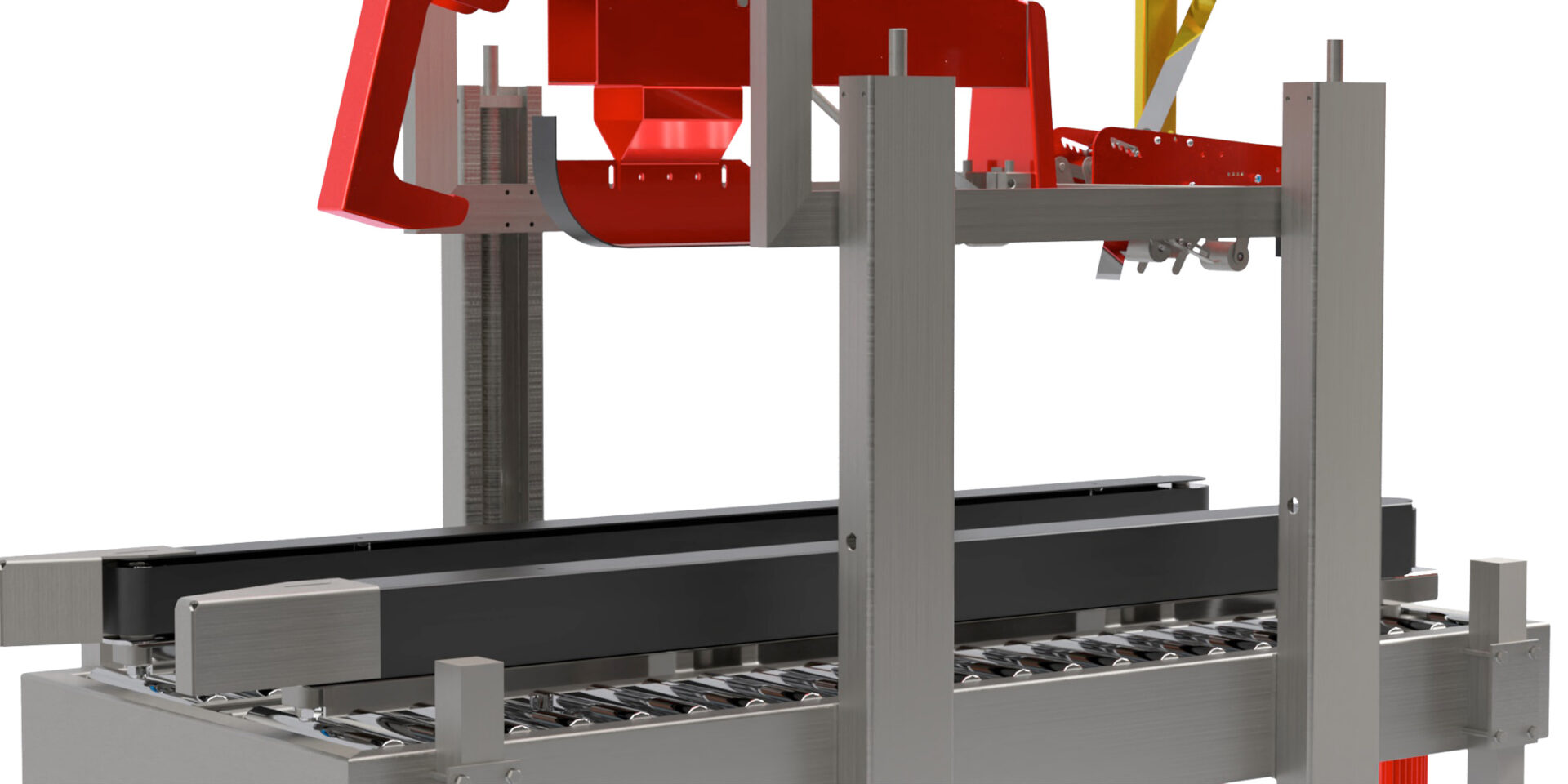

Las propiedades resistentes y flexibles del plástico ajustan los pliegues del fardo o empaque final para asegurar un enfardado industrial óptimo sin causar daños al producto.

Beneficios principales

- Ahorro de costos de mano de obra en el enfardado de los six pack, three pack o four pack.

- Tiene la capacidad de integrarse con las envasadoras asépticas y ultralimpias ESSI para mejorar la eficacia del sistema, reduciendo al máximo la intervención manual en un proceso automático y práctico.

- Producciones más largas entre cambios de rollo debido a la capacidad de las bobinas para manejar diferentes diámetros.

- Reducción de personal de forma significativa con relación a procesos manuales del mismo tipo.

- Conserva las condiciones de higiene del producto durante todo el proceso.

Plus diferencial del Bagger

El diseño de los sistemas de sellado del fardo permite la visibilidad de la marca en anaqueles, garantizando mayor posicionamiento en el mercado.

Métricas e indicadores esperados

OEE (número de fardos y datos de producción)

Detalles de fabricación

El equipo Bagger ESSI está fabricado en acero inoxidable 304 y otros materiales de ingeniería que incluyen plásticos y compuestos especializados, aptos para el contacto con alimentos.

Aspectos sobre el mantenimiento

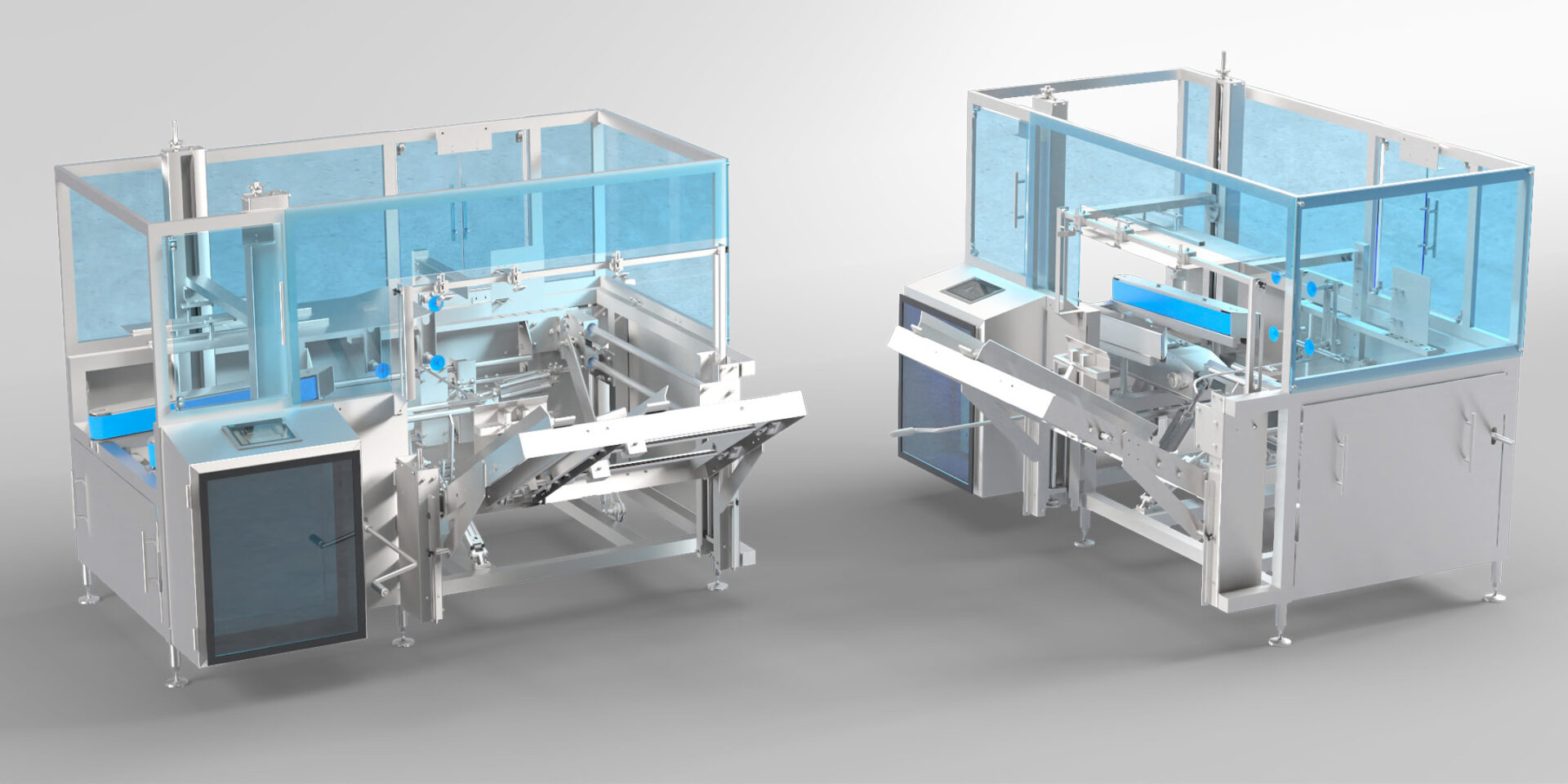

Todos los equipos de final de línea ESSI son sistemas altamente funcionales que requieren de un control y esquema de mantenimiento para garantizar y asegurar los indicadores de confiabilidad, disponibilidad y rendimiento en producción.

ESSI cuenta con un portafolio de servicios y repuestos para la realización oportuna de los mantenimientos preventivos y correctivos. También ofrece un sistema de asistencia técnica remota y presencial oportuna en todo momento..

ESSI

Soluciones relacionadas

End of line

Bagger

Technical characteristics of the equipment

Production volume: 15 fardossix packs per minute for presentations of 900 ml and 1,000 ml.

Most relevant features

The Bagger ESSI are designed for the industrial entaling of liquid bags previously arranged in flexible packaging by a packaging machine. The entamed process is carried out automatically by the Bagger in order to achieve a final product with three quality seals: one vertical and two horizontal in six pack, three pack or four pack presentations reaching up to 5,400 u/h.

The Bagger ESSI offers a bag receiver, controlled and arranged vertically, in a container for individual units that can be configured for bales of three and six units according to the target market niche.

Its compact adjustment allows a high-precision positioning, thanks to a servo-assisted movement that, supported by a system of optical sensors, counts and relates the position that the bag should have in its container according to the final delivery quantities.

The resistant and flexible properties of the plastic adjust the folds of the bale or final packaging to ensure optimal industrial bale without causing damage to the product.

Main benefits

- Savings in labor costs in the bundle of the six packs, three packs or four packs.

- It has the ability to integrate with ESSI aseptic and ultra-clean packaging machines to improve the effectiveness of the system, minimizing manual intervention in an automatic and practical process.

- Longer productions between roll changes due to the ability of the coils to handle different diameters.

- Significant reduction of personnel in relation to manual processes of the same type.

- Maintains the hygiene conditions of the product throughout the process.

Bagger's differential plus

The design of the bale sealing systems allows the visibility of the brand on shelves, guaranteeing greater positioning in the market.

Expected metrics and indicators

OEE (Number of bales and production data)

Manufacturing details

The Bagger ESSI equipment is made of 304 stainless steel and other engineering materials that include specialized plastics and compounds, suitable for contact with food.

Aspects of maintenance

All ESSI end-of-line equipment are highly functional systems that require a control and maintenance scheme to guarantee and ensure indicators of reliability, availability and production performance.

ESSI has a portfolio of services and spare parts for the timely realization of preventive and corrective maintenance. It also offers a timely remote and face-to-face technical assistance system at all times..