UL Ultra Clean Packaging Machine

- Home

- soluciones

- Bottling

- UL Ultra Clean Packaging Machine

Bottling

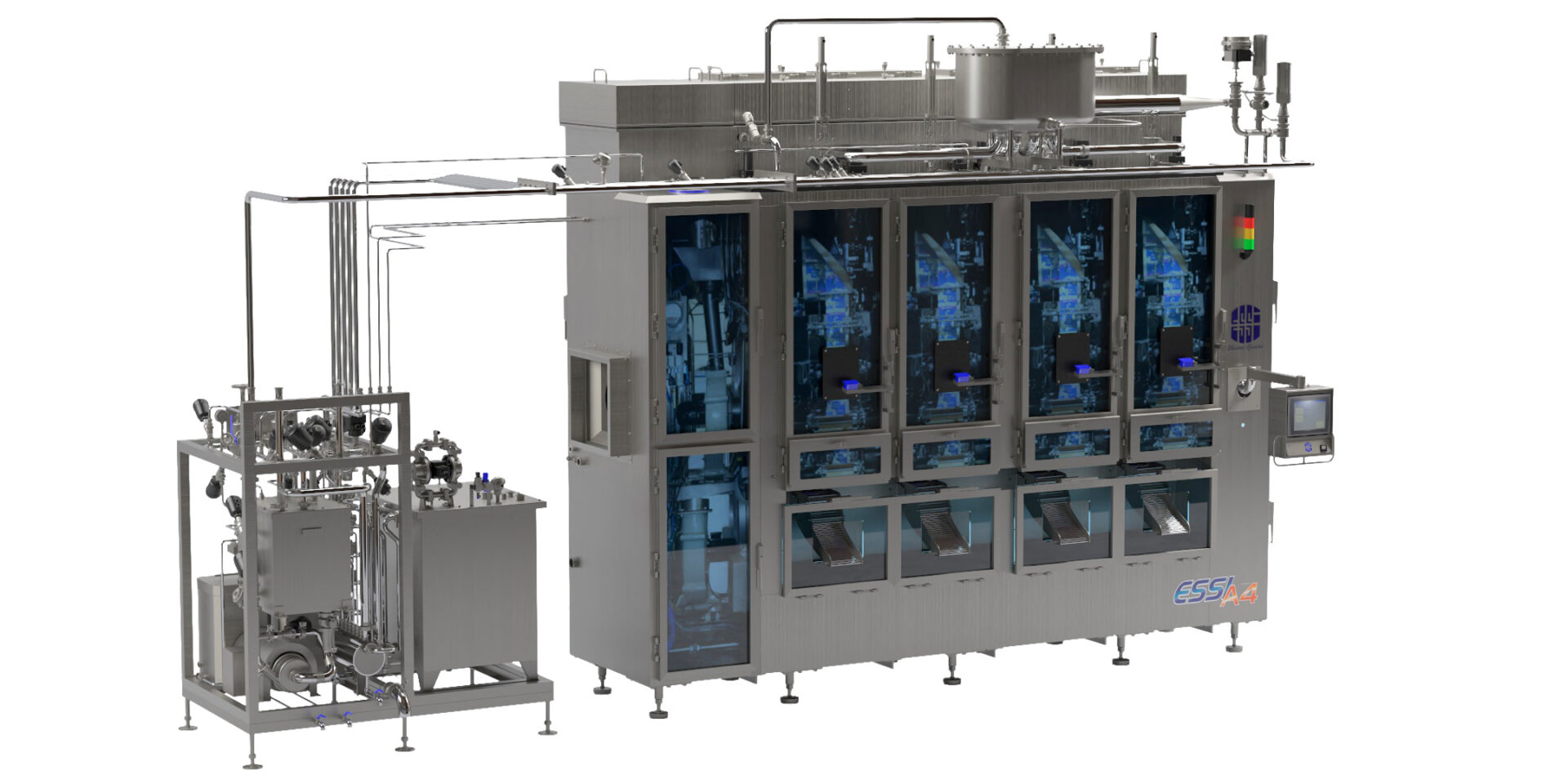

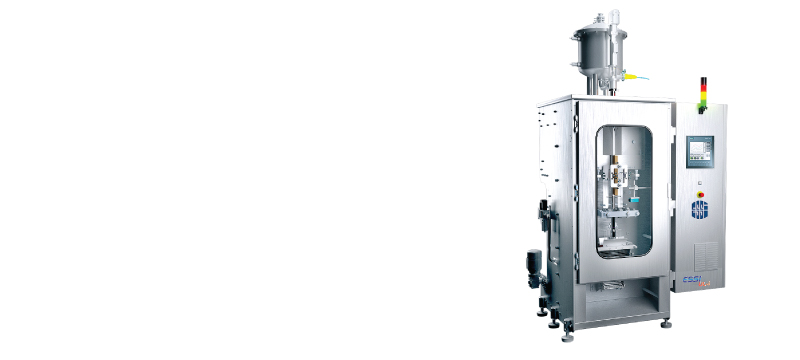

Ultra clean packaging machine UL

Technical characteristics of the equipment

The Ultralimpia UL packaging machine is designed for sachet packaging of pasteurized liquids such as milk, yogurt or juices in presentations ranging from 200 ml to 1,000 ml, reaching packaging capacities of 3000L/h Per head, according to its version or specific requirements. Its design can be adapted for the packaging of products with higher viscosity.

It is characterized by the fact that all the active parts that determine the forming, filling and welding operations of the sachet are grouped in a closed enclosure, under a preparatory phase of sanitation.

The Ultraclean UL Packaging Machine, in turn, has a cabin with UV lamps to minimize the bacterial load coming from the plastic.

This equipment includes an Automatic CIP that guarantees its proper cleaning and at the same time has a remote connection via Ethernet.

Most relevant features

Proceso de limpieza

0

Limpieza interna o CIP: asegura las condiciones adecuadas para el envasado del producto, realizando una limpieza de forma semiautomática que proviene del sistema CIP adicionado a la envasadora, una vez está lista para su desinfección. Limpieza externa o COP: limpieza manual realizada a los elementos de la envasadora que requieren una limpieza manual para retirar los residuos de producto que se pueden depositar en ellos.

Our Work

( 0 +)

More than 100 large and small projects are completed. It is an attempt to work with effort and passion

Member

( 0 +)

The team of more than 1000 engineers and leading experts are working day and night

The UL Ultra Clean Packaging Machine has two main processes:

- Cleaning process:

Internal cleaning or CIP: Strong span ensures the appropriate conditions for the packaging of the product, performing a semi-automatic cleaning that comes from the CIP system added to the packaging machine, once it is ready for disinfection.

Limpieza externa o COP: limpieza manual realizada a los elementos de la envasadora que requieren una limpieza manual para retirar los residuos de producto que se pueden depositar en ellos.

- Production process

Liquid products are packaged ensuring commercial sterility without altering their nutritional value, physicochemical and organoleptic characteristics.

- Versatility in production times

The packaging machine has speed variators that allow it to adapt to production capacity depending on the sachets that the customer defines in the process.

- Easy operation

Control and cleaning operations are configurable from an operations screen.

Main benefits of the UL Ultraclean Packaging Machine

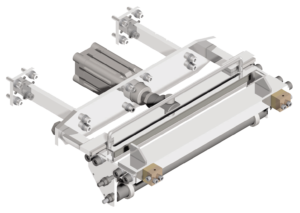

The Packaging Machine Ultralimpia ULIt has a splicing machine, which reduces downtime and reduces polyethylene waste thanks to the automatic splicing between the coils.

As a result of the connection of the PLC with the servomotor controllers,the operator can dispose of the product flow from the screen according to the presentation indicated above.

Capture dates and other control data required by the product, in an accurate and aesthetic way.

Through an operations screen, the instructions entered by the user are converted to the PLC language; guaranteeing an efficient and reliable process. From there, the cleaning processes are controlled. and packaging.

The change of presentation is 100% automatic and is done from the control screen in a matter of seconds.

Manufacturing details

The UL Ultraclean Packaging Machine is made of 304 and 316L stainless steel, guaranteeing asepsis in the packaging process during direct contact with the product, giving it the best conditions in chemical cleaning.

All parts are made of materials that allow the asepsis to be maintained within the packaging process.

Expected metrics and outstanding indicators from the team

- Zero production stops due to change of roll.

- 100% automatic change of presentations.

- Low operating costs.

Aspects of maintenance

The constant work of the ESSI packaging equipment and their efficient operation require a control and maintenance scheme to ensure the assurance of the indicators of reliability, availability and performance in production.

In this way, ESSI has a portfolio of services and spare parts for the timely performance of preventive and corrective maintenance, offering a timely remote and face-to-face technical assistance system at all times.