ESSI A1 Aseptic Packaging Machine

- Home

- soluciones

- Bottling

- ESSI A1 Aseptic Packaging Machine

Bottling

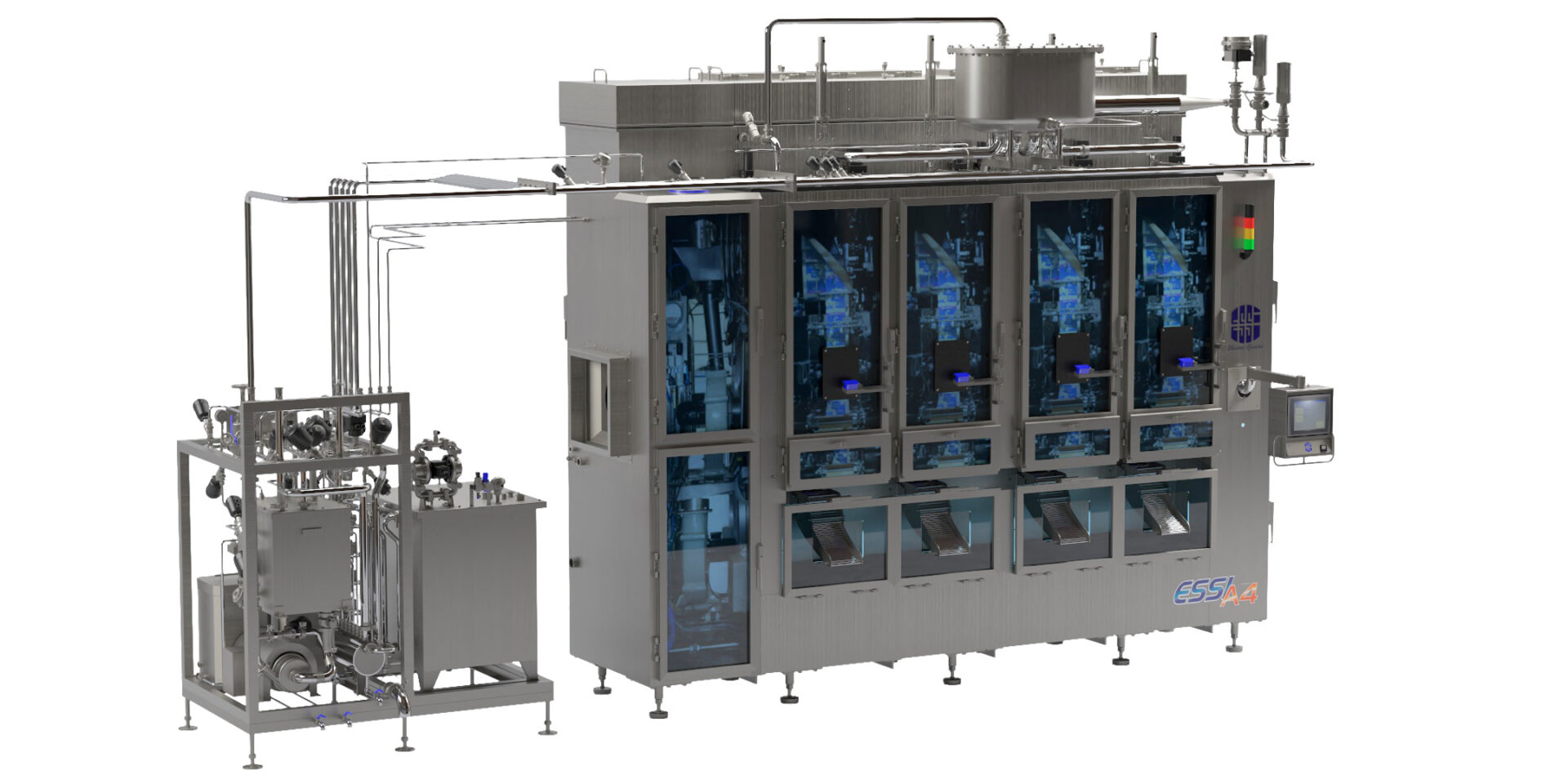

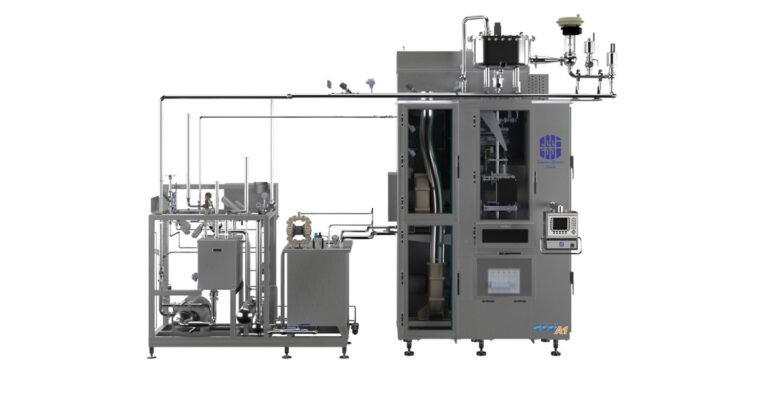

ESSI A1 Aseptic Packaging Machine

Technical characteristics of the equipment

It is designed for the aseptic packaging of liquids in bags such as water, milk, cream, ice cream base, juices and nectars; treated by UHT sterilization processes. The ESSI A1 Aseptic Packaging Machine has 1 production head with a packaging capacity from 200 ml to 1,000 ml.

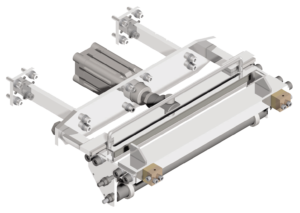

It guarantees aseptic conditions throughout production, since all the active parts that determine its forming, filling and sealing operations of the sachet are grouped in a sterile closed enclosure in a preparatory phase. Likewise, the packaging material is sterilized prior to contact with the product.

This equipment includes an Automatic CIP that guarantees its proper cleaning and at the same time has a remote connection via Ethernet.

Most relevant features

The ESSI A1 Aseptic Packaging Machine has three main processes:

- Proceso de limpieza: eliminación de toda la suciedad depositada sobre una superficie determinada, interna CIP y externa COP.

- Sterilization process: eliminación de todo tipo de microorganismos existentes sobre una superficie perfectamente limpia. It should be noted that it is impossible to sterilize without proper prior cleaning.

- Packing process: Packaging of liquid products, ensuring their commercial sterility without altering their nutritional value, physicochemical and organoleptic characteristics. It should be noted that liquid products can be marketed at room temperature.

Simultaneous packaging of versatility of presentations

The ESSI A1 Aseptic Packaging Machine is ideal for increasing or maintaining production in different product presentations, according to existing requirements. It allows simultaneous packaging versatility of presentations from 200 ml to 1000 ml; by its heads and at variable speeds each, depending on the supply capacity of the product online, either directly from a sterilizer or fed from an aseptic tank.

Preserve the properties of the product

En efecto, su diseño garantiza la conservación de las características microbiológicas y fisicoquímicas de los productos a envasar, tales como leche ultrapasteurizada UHT y larga vida, las cuales pueden ser comercializados a temperatura ambiente.

Plus differential of the ESSI A1 Aseptic Packaging Machine

Versatility of packaging in different presentations, which can be configured automatically from the operations screen.

Main benefits

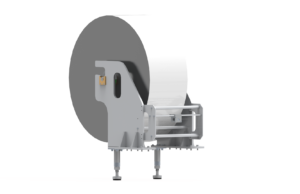

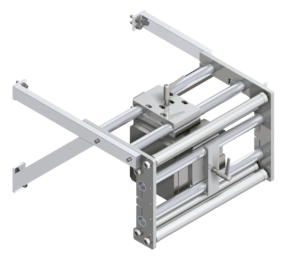

The roll holder has a versatile and simplified design that ensures the support of rolls from 25 to 220 kg, the latter allows to achieve continuous productions of up to 11 hours for the packaging of 1L presentations.

The bag packaging machine has semi-automatic splice, which reduces downtime by considerably reducing polyethylene waste.

Accurate calibration of the amount of product to be packaged, regulated directly from the operations screen.

The touch screen, called panel view, converts the instructions entered by the user to the PLC language, guaranteeing an efficient and reliable process in the basic operability of the equipment. From there, the cleaning, sterilization and packaging processes are controlled.

A dating system that performs high-quality printing with the required data on the plastic film.

The standard ESSI A1 Aseptic Packaging Machine has an Automatic CIP included; responsible for storing, mixing and pumping the compounds used for cleaning the packaging machine.

The ESSI team of experts provides training, accompaniment and technical support in each implementation of its technological solutions.

Expected metrics and outstanding indicators from the team

- Zero production stops due to change of roll.

- Roll change every 11 hours in 1L presentations.

- Low operating costs.

- Change of presentation without the need to perform a CIP.

- Immediate technical support system via Ethernet.

Manufacturing details

The mechanical systems of the ESSI A1 Aseptic Packaging Machine are made of 304, 316L stainless steel and other engineering materials suitable for contact with food. In addition, They provide you with the best conditions in chemical cleaning.

Aspects of maintenance

All ESSI packaging equipment are highly functional systems that require a control and maintenance scheme to guarantee and ensure the indicators of reliability, availability and performance in production.

ESSI has a portfolio of services and spare parts for the timely execution of preventive and corrective maintenance. It also offers a timely remote and face-to-face technical assistance system at all times.