Encartonator

- Home

- soluciones

- End of line

- Encartonator

End of line

Encartonator

Most relevant features

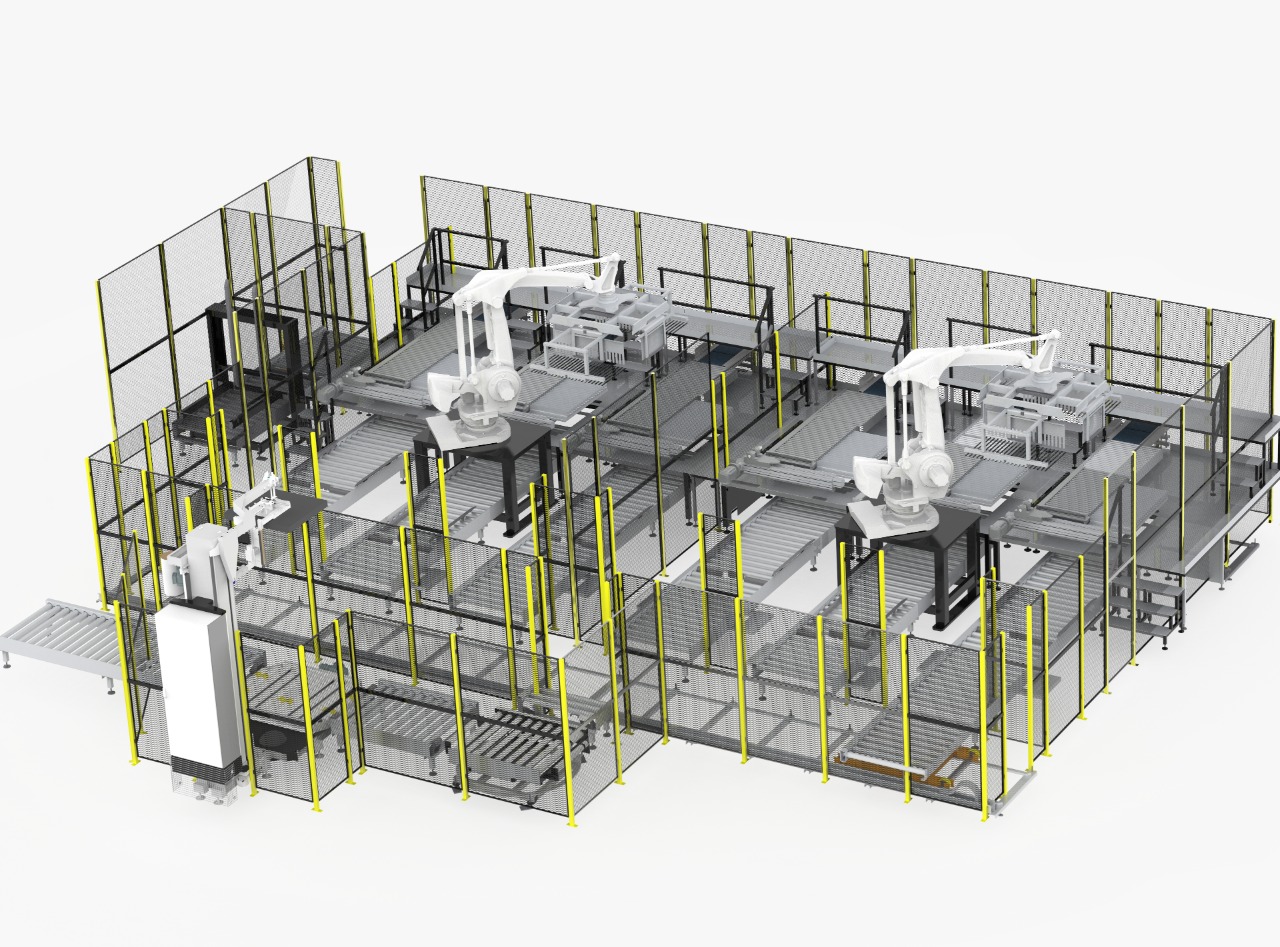

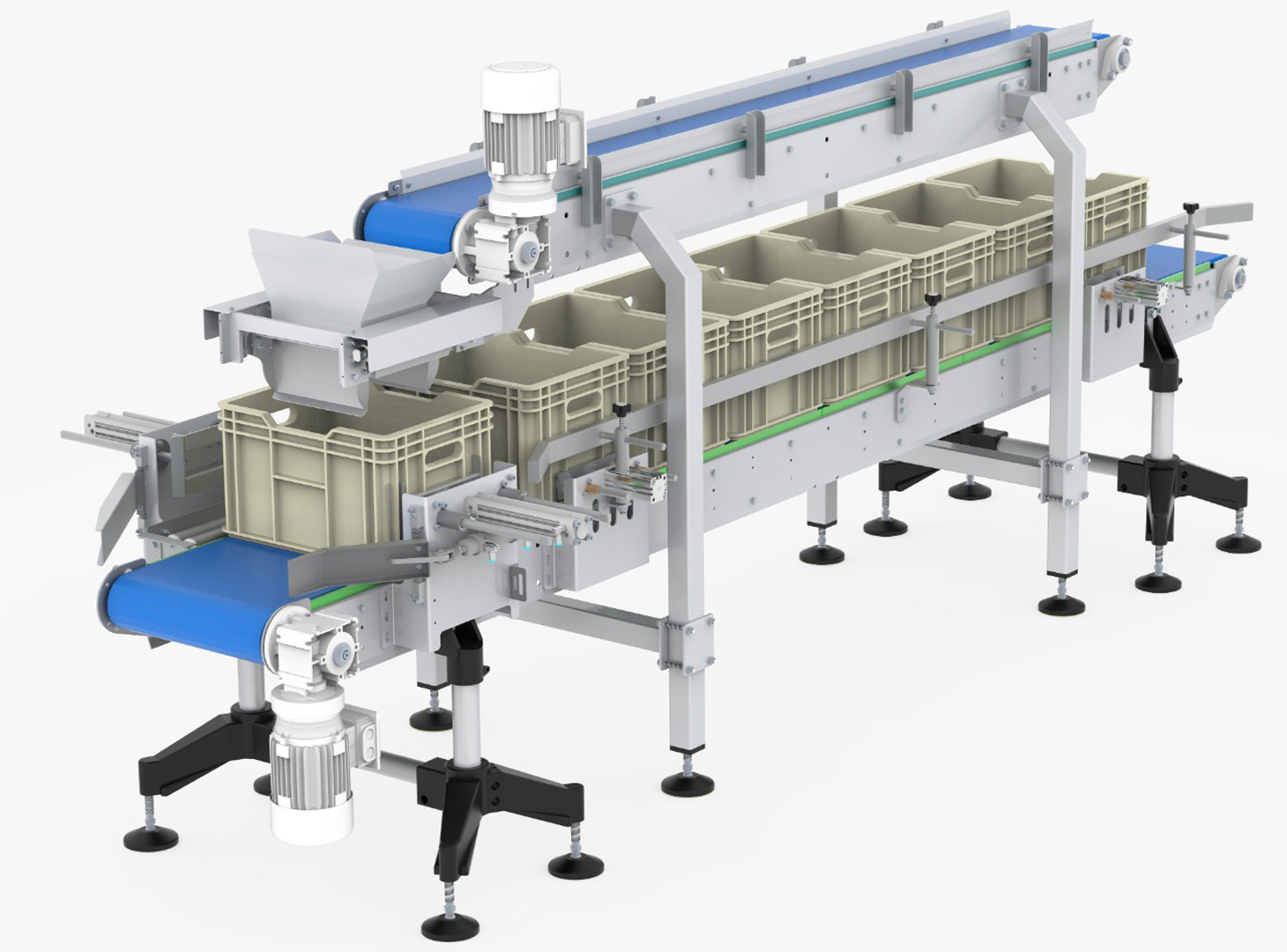

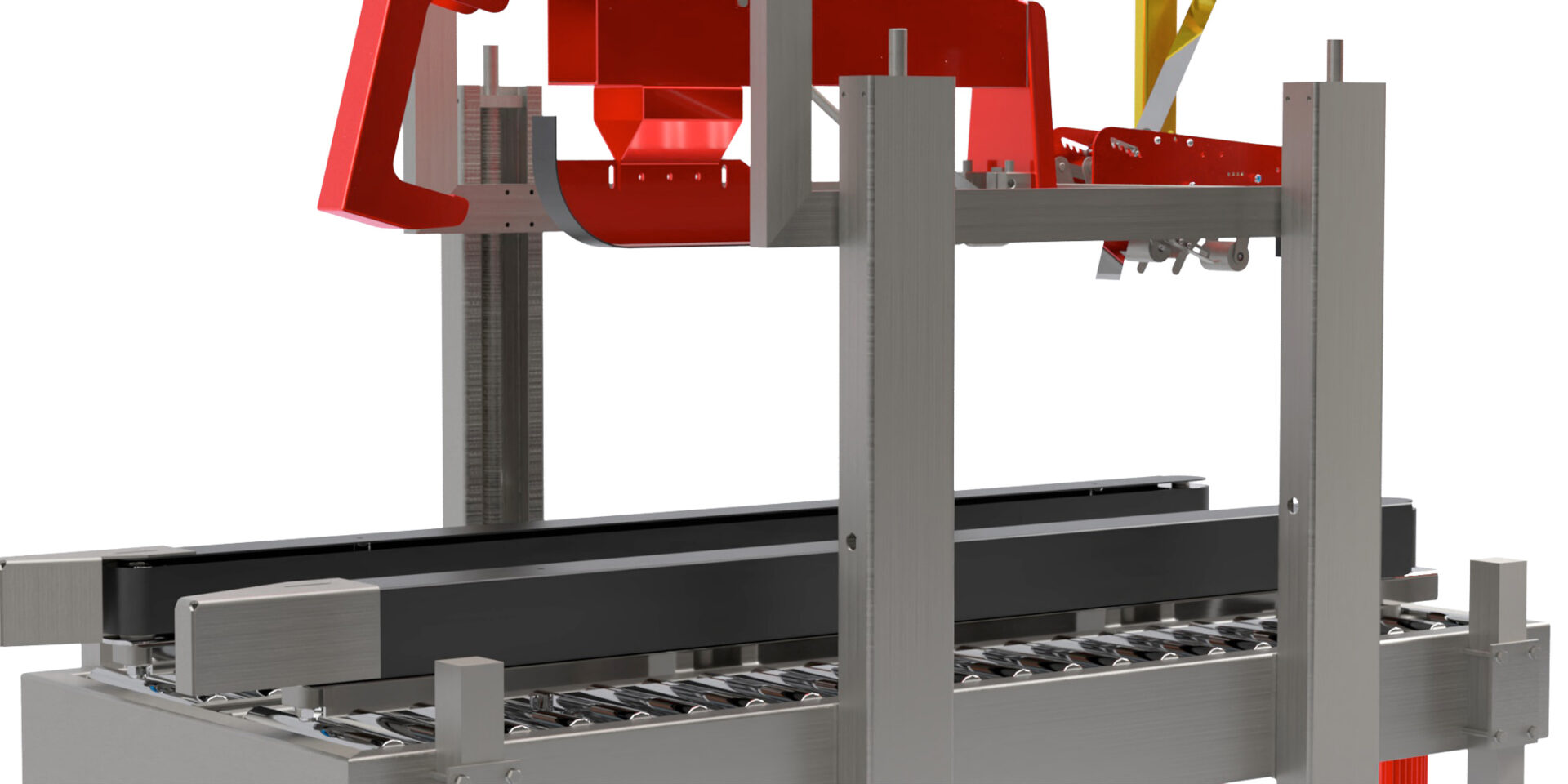

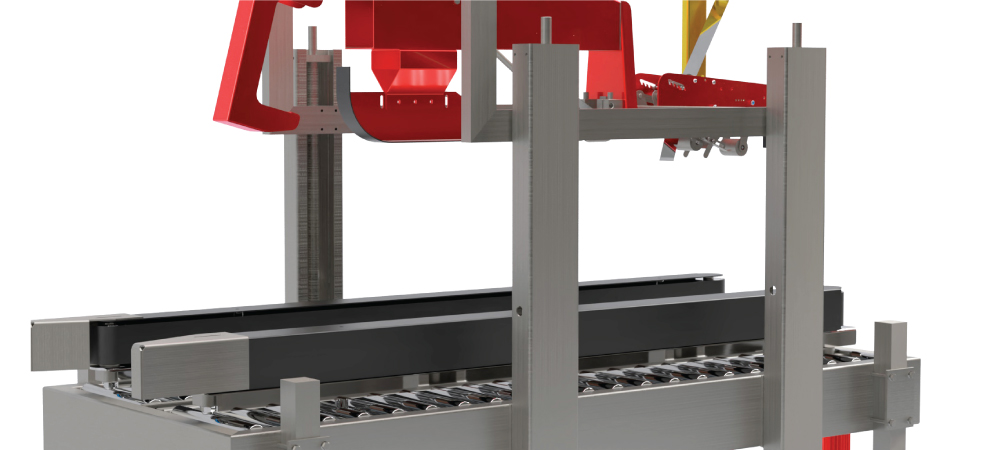

The automatic high-speed box assembly, GPK-40H18, is a device designed for automatic box assembly with a speed of up to 18 cardboard boxes per minute. The team is responsible for assembling and sealing the boxes at the bottom.

The automatic cartoner has a practical manual adjustment that allows the assembly of different sizes of boxes.

It has a box detection sensor at the exit of the system that detects the accumulation of cardboard on the line, this sensor can be extended to the following conveyor belt in order to read or detect the maximum storage capacity of the line and thus stop its operation; achieving savings in air consumption and making maximum use of the integration of the packaging line.

Main benefits

- The equipment is configurable to the end-of-line working system thanks to its versatility of sizes and continuous production per minute.

- Savings from indirect manufacturing costs.

Plus differential of the Encartonator

- Rational design: the process of forming, folding and sealing is carried out simultaneously, which translates into advantages in production times.

Expected metrics and indicators

- 18 boxes per minute.

Manufacturing details

The GPK-40H18 automatic packaging machine is a robust construction, made of 304 stainless steel and other engineering materials, including specialized plastics and compounds that improve the life of the product.

Aspects of maintenance

All ESSI end-of-line equipment are highly functional systems that require a control and maintenance scheme to guarantee and ensure indicators of reliability, availability and production performance..

ESSI has a portfolio of services and spare parts for the timely realization of preventive and corrective maintenance. It also offers a timely remote and face-to-face technical assistance system at all times.