ESSI A4 Aseptic Container

- Home

- soluciones

- Bottling

- ESSI A4 Aseptic Container

Bottling

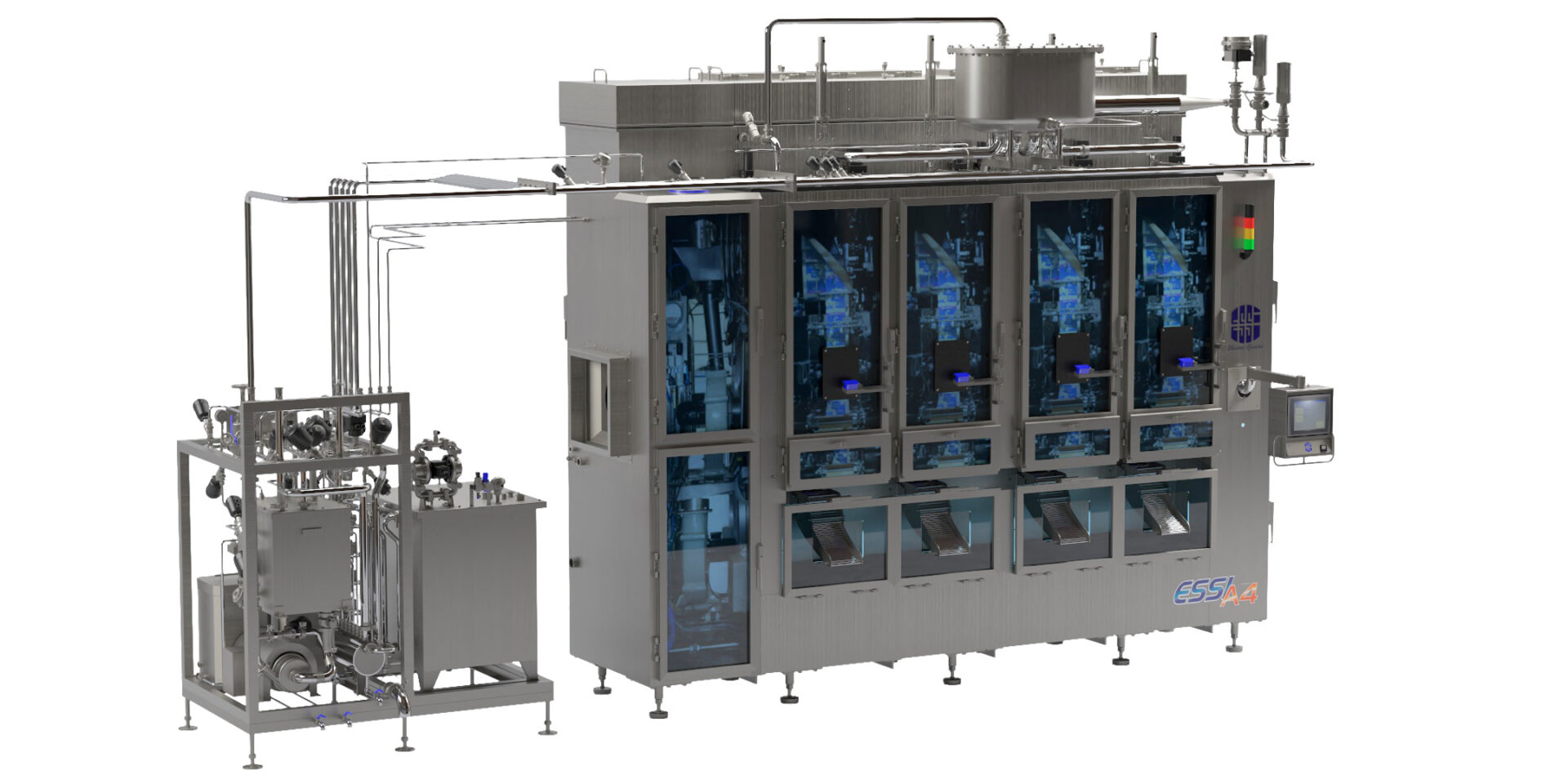

ESSI A4 Aseptic Container

Technical characteristics of the equipment

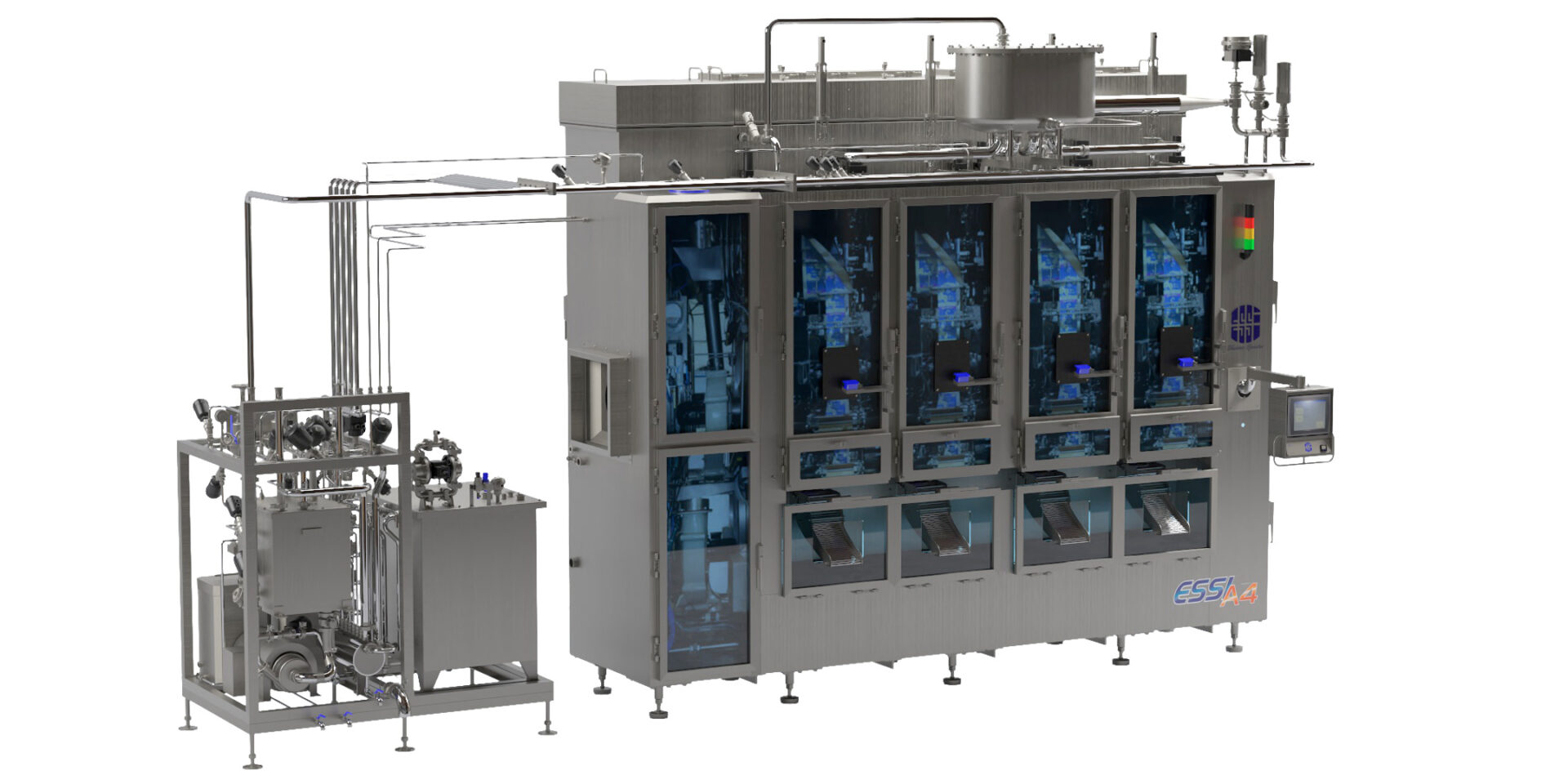

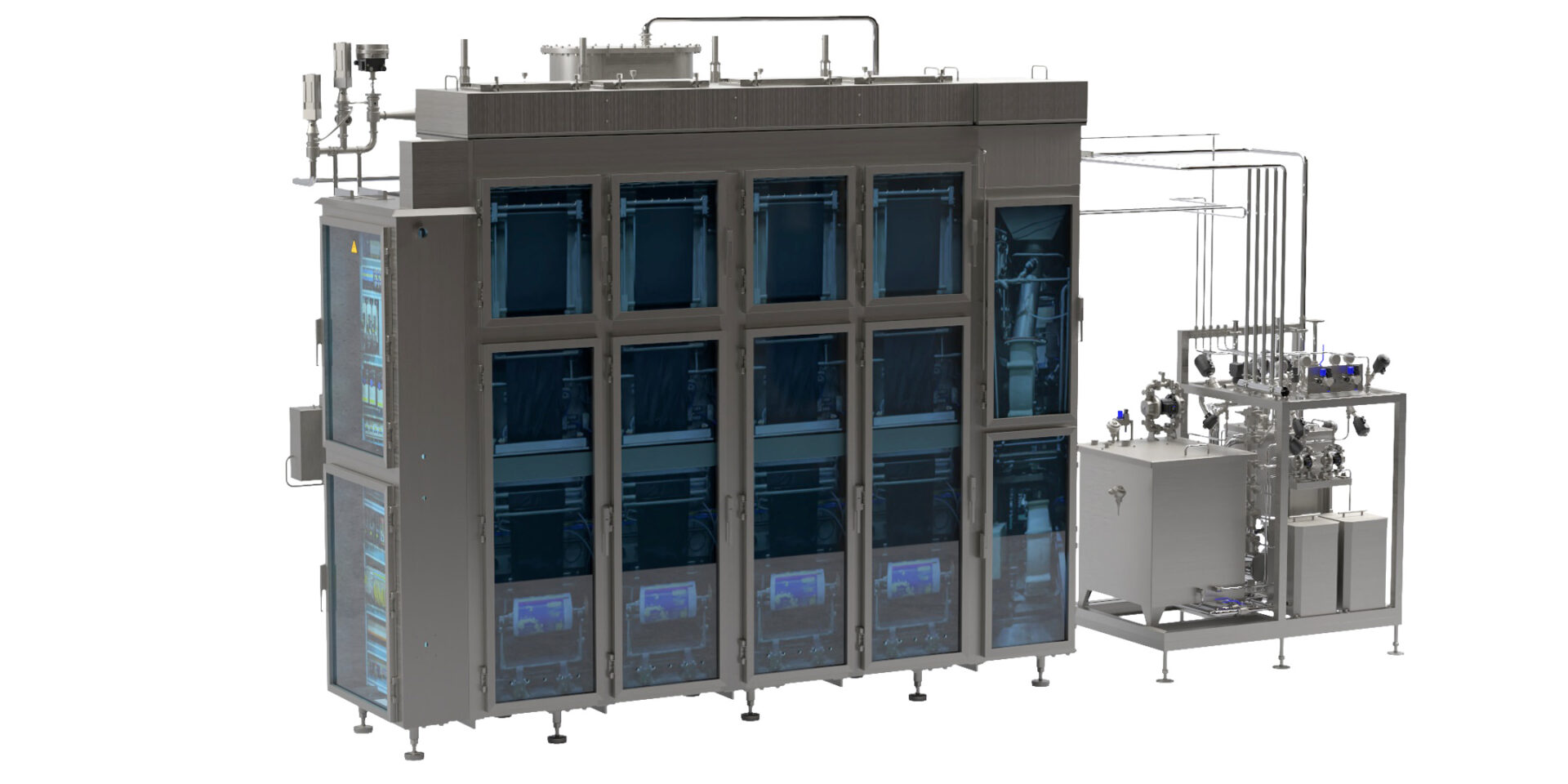

The ESSI A4 Aseptic Packaging Machine is the ideal solution for the packaging of liquids in a bag or aseptic sachet such as water, milk, cream, ice cream base, juices and nectars treated by UHT sterilization processes. It has 4 production heads independent of each other, each with packaging capacity from 200 ml to 1,000 ml.

It also incorporates a sterile closed enclosure, which groups all the active parts that produce the forming, filling and sealing operations of the sachet, guaranteeing aseptic conditions throughout production. Likewise, the packaging material is sterilized prior to contact with the product.

This equipment includes an automatic CIP that guarantees its proper cleaning and at the same time has a remote connection via Ethernet.

Most relevant features

The ESSI A4 Aseptic Packaging Machine has three main processes:

- Internal (CIP) and external (COP) cleaning process: characterized by the removal of all dirt deposited on a given surface.

- Sterilization process: After the cleaning process, all types of existing microorganisms are removed on a perfectly clean surface. We can understand the importance of prior cleaning before performing sterilization.

- Packing process: Liquid products are packaged ensuring commercial sterility without altering their nutritional value, physicochemical and organoleptic characteristics. This is how it is marketed at room temperature.

The ESSI A4 Aseptic Packaging Machine is made up of four heads Of packaging. However, each of them works independently by sharing the same asepsis condition, that is, the machine can simultaneously pack presentations of 200 ml and 1000 ml in different heads. The above according to the online product supply capacity, either directly from a sterilizer or fed from an aseptic tank.

Plus differential of the ESSI A4 Aseptic Packaging Machine

It makes possible the versatility of packaging in different presentations and allows the automatic configuration of presentations from the operations screen.

Main benefits

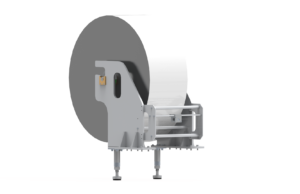

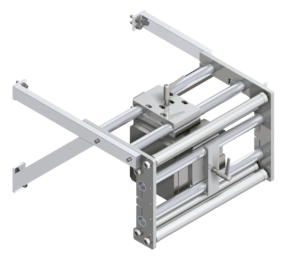

The roller holder of the ESSI A4 Aseptic Packaging Machine has a versatile design that allows you to support rolls from 25 to 220 kg. The latter allows you to achieve continuous productions of up to 11 hours para el envasado de presentaciones de 1L.

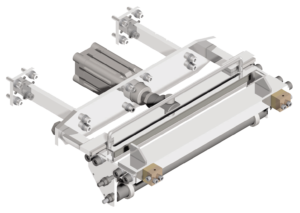

The splicing tool ensures the union of the two plastic rolls when one of them is exhausted. This type of semi-automatic splice reduces downtime, considerably reducing polyethylene waste.

The ESSI A4 Aseptic Packer performs an accurate calibration of the amount of regulated product to be packaged directly from the panel view, thus reducing waste and time for change of presentation.

Through a control screen, the basic operation of the equipment is carried out, which allows you to supervise the main functions such as the control of the cleaning, sterilization and packaging processes.

The ESSI A4 Aseptic Packaging Machine performs a high-quality printing of the dates of packaging, expiration, batch and other variable data on the plastic film.

The standard ESSI A4 Aseptic Packaging Machine has an automatic CIP included, which stores, mixes and pumps the different compounds that are used for the cleaning of the packaging machine.

The ESSI team of experts provides training, accompaniment and technical support in each implementation of its technological solutions.

Expected metrics and outstanding indicators from the team

- Zero production stops due to change of roll.

- Change of roll every 11 hours in 1 L presentations.

- Low operating costs.

- Change of presentation without the need to perform a CIP.

- Immediate technical support system via Ethernet.

Manufacturing details

The ESSI A4 Aseptic Packaging Machine is made up of mechanical systems, built of 304 and 316L stainless steel, guaranteeing asepsis in the packaging process during direct contact with the product and giving it the best conditions in chemical cleaning.

Aspects of maintenance

All ESSI packaging equipment are highly functional systems that require a control and maintenance scheme to ensure the assurance of the indicators of reliability, availability and performance in production.

In this way, ESSI has a portfolio of services and spare parts for the timely performance of preventive and corrective maintenance, offering a timely remote and face-to-face technical assistance system at all times.

Consult the maintenance plans with the team of ESSI technical support experts.