Packer

End of line

Packer

Technical characteristics

Production volume: counting of programmable units according to the need for packaging and presentation.

Custom-made design.

Most relevant features

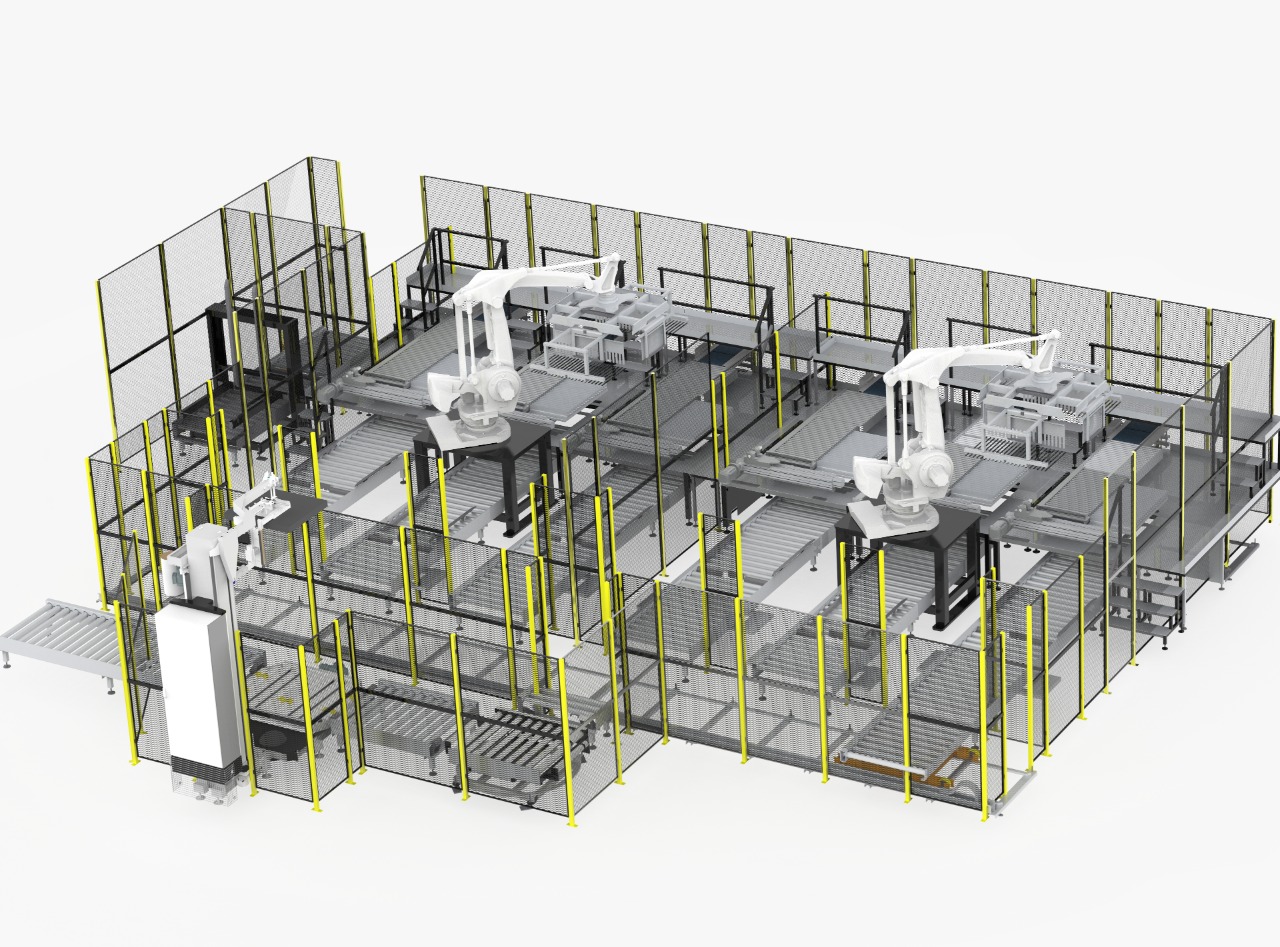

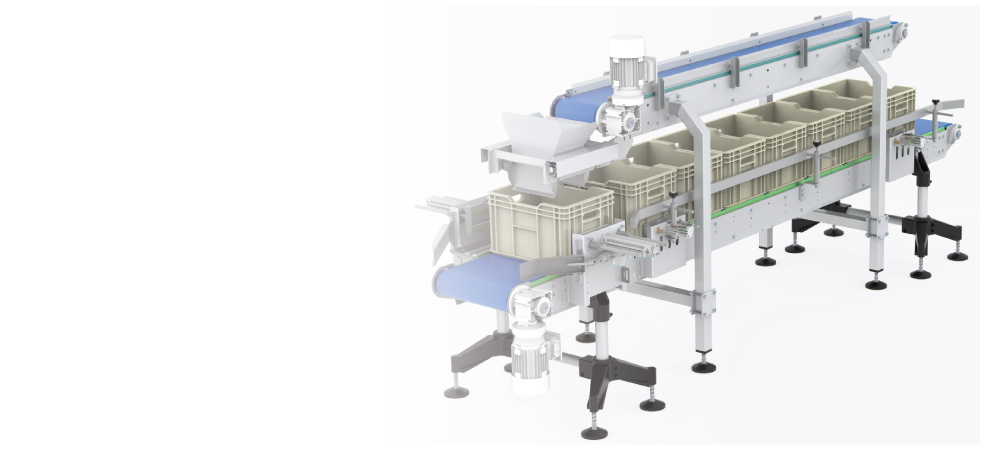

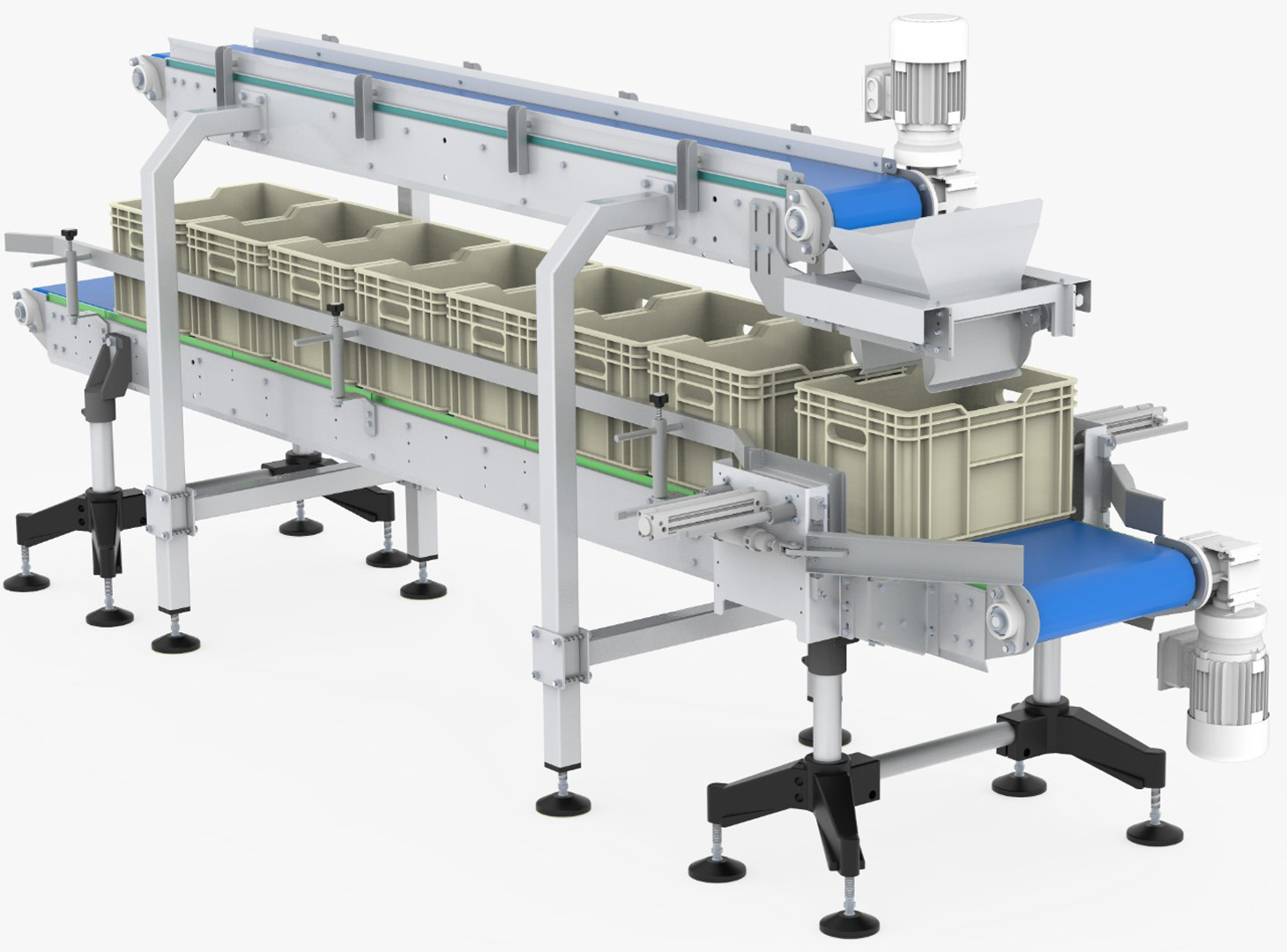

The Packer system is a package of elements and bands that work together with the aim of transporting, counting and organizing products considered to be packaged or small content.

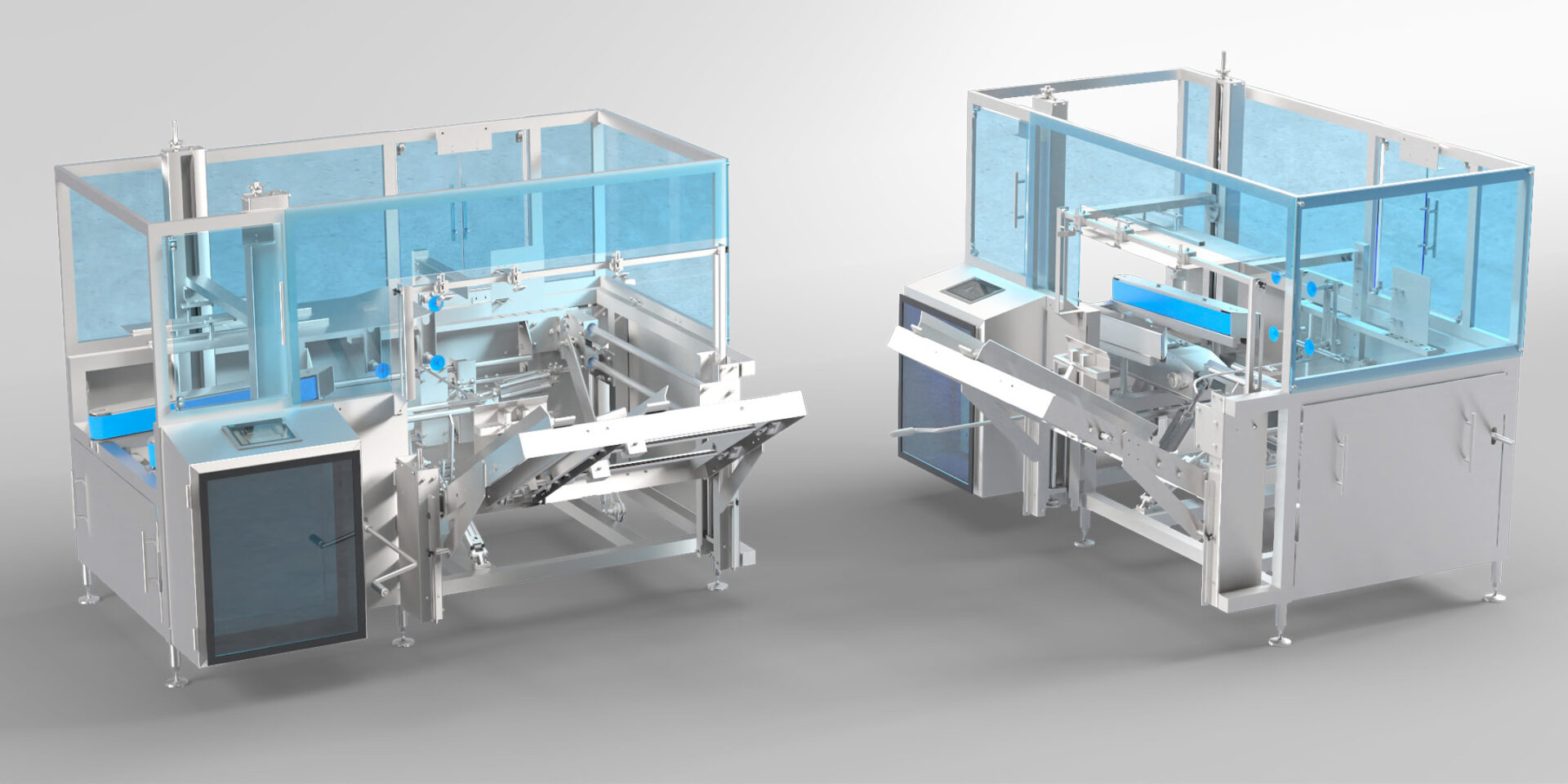

It is designed for the handling of product presentations in bags from 110 ml to 800 ml that will finally be available in a plastic bucket or cardboard box.

Main benefits

- The Packer system can be integrated into product or band transport systems. It has the ability to count the product units to be deposited in plastic buckets or cardboard boxes according to the requirements of the production plants.

- The Packer system has a high capacity to detect the product, due to its versatility in the location or positioning of sensors and control elements.

- Its versatility in the location of different control elements for boxes and buckets manages to handle different sizes and packaging characteristics.

Plus differential of the Packer system

- It has an advanced sensitive optical sensor calibration system that ensures the counting of a high variety of product sizes in the bag.

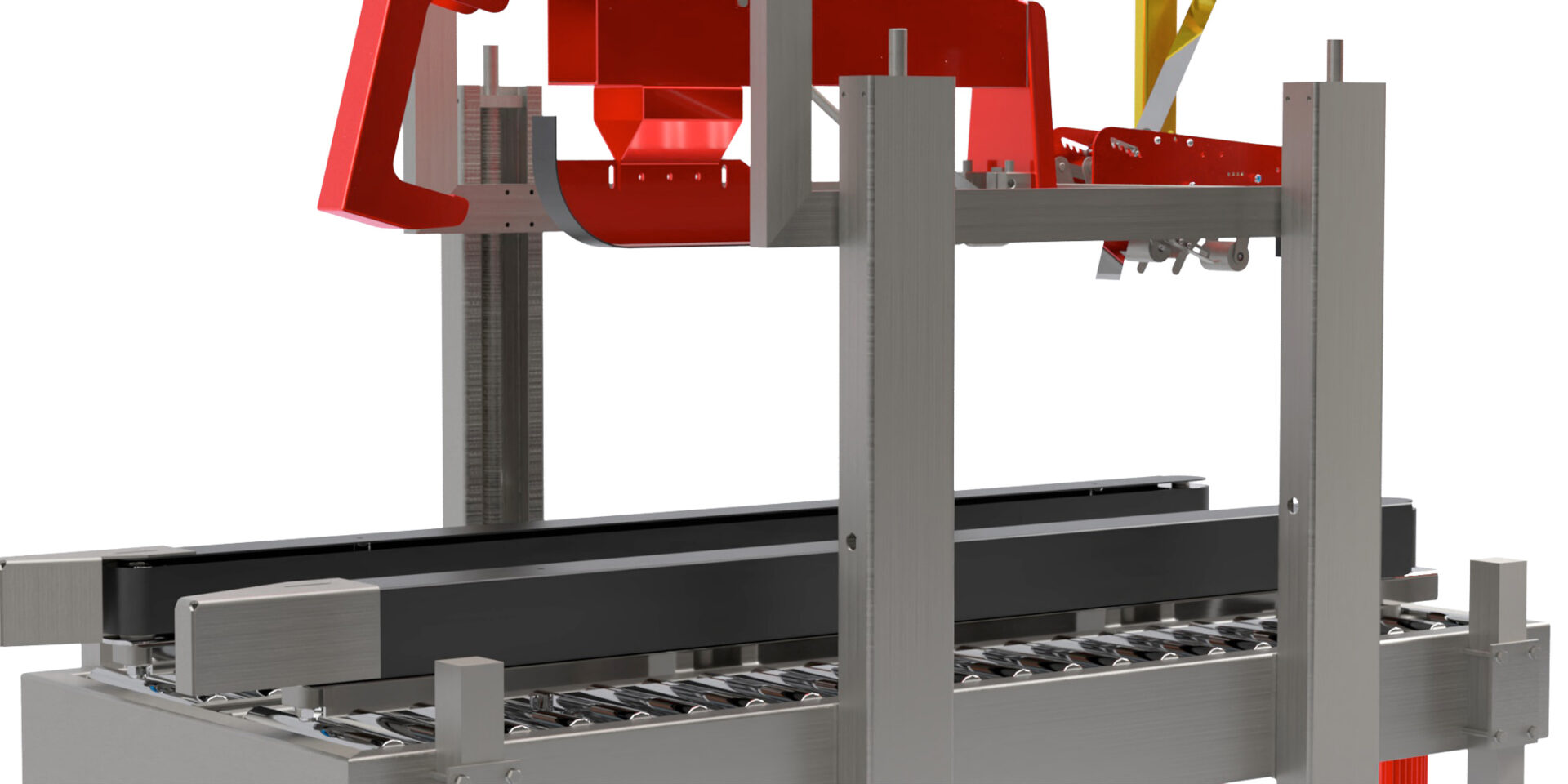

- The Packer system is suitable for managing the different product containers, managing to fit cardboard boxes or plastic buckets in very simple steps and taking into account the properties of the final packaging.

- Its stirring system distributes the product safely, preventing it from protruding from its container while it is protected in the vertical stacking systems.

- This system can be configured according to the production processes of each plant and integrated with box assembly and sealing systems, reducing the costs, time and the amount of personnel available in a packaging line.

Expected metrics and outstanding indicators from the team

- It has a unit counting system.

- It has automatic management systems and accumulation of plastic buckets or cardboard boxes.

Manufacturing details

The Packer system is made of 304 stainless steel, engineering plastic materials and specialized compounds suitable for contact with food; while ensuring the hygiene of the process and the long service life of the equipment.

Aspects of maintenance

The maintenance of the system is simple and programmed, according to the wear and tear presented in its components or the time of use and/or operation of the equipment..

In case of sudden intervention, access to its components can be done quickly, even in the change of some critical element of the system.

All ESSI End of Line teams are highly functional systems that require a control and maintenance scheme to guarantee and ensure indicators of reliability, availability and production performance.

ESSI has a portfolio of services and spare parts for the timely realization of preventive maintenance and corrective maintenance interventions. It also offers a timely remote and face-to-face technical assistance system at all times.