Palletized with robotic arm

- Home

- soluciones

- End of line

- Palletized with robotic arm

End of line

Palletized with robotic arm

Technical characteristics of the equipment

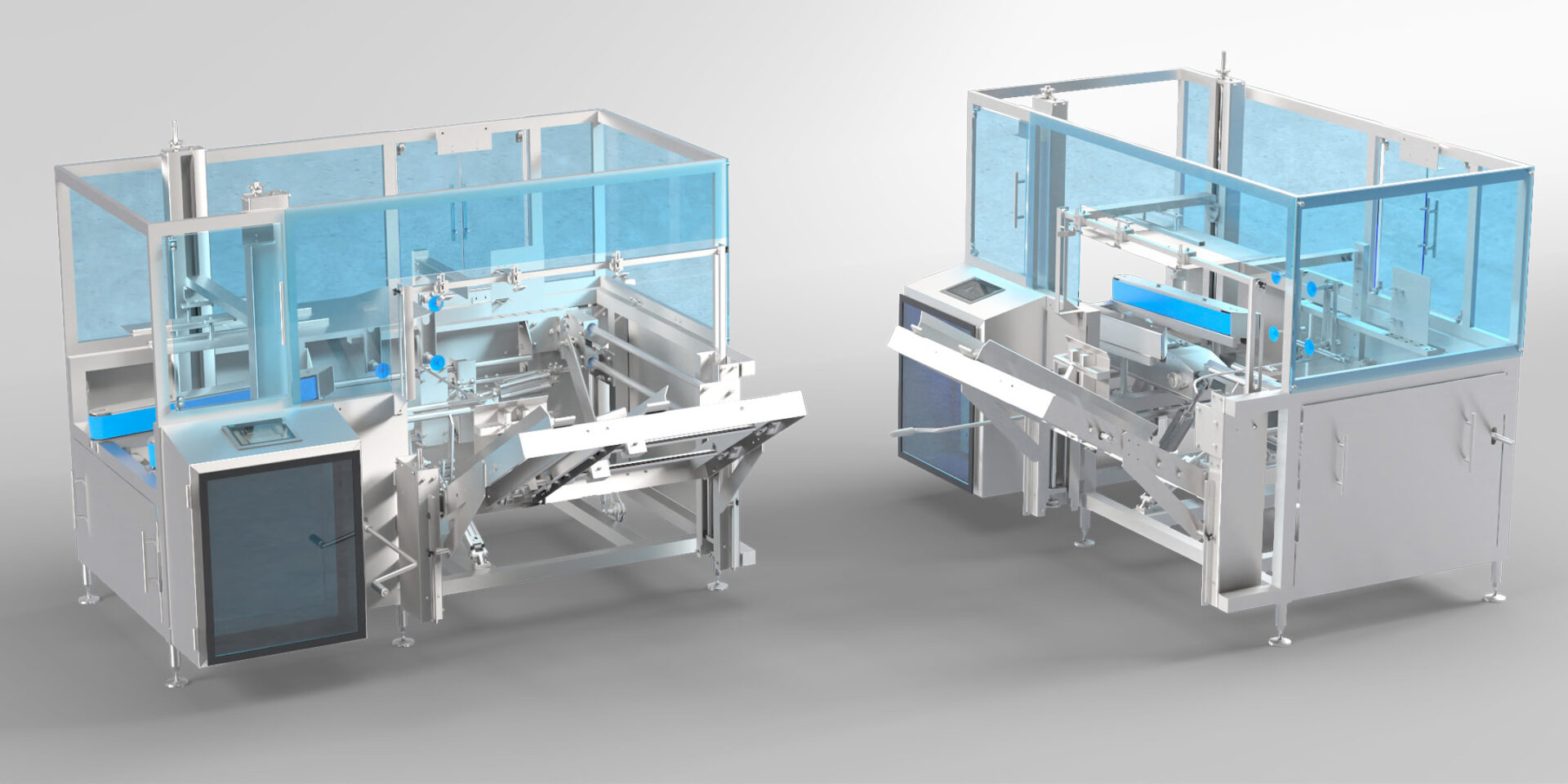

Custom-made design.

Most relevant features

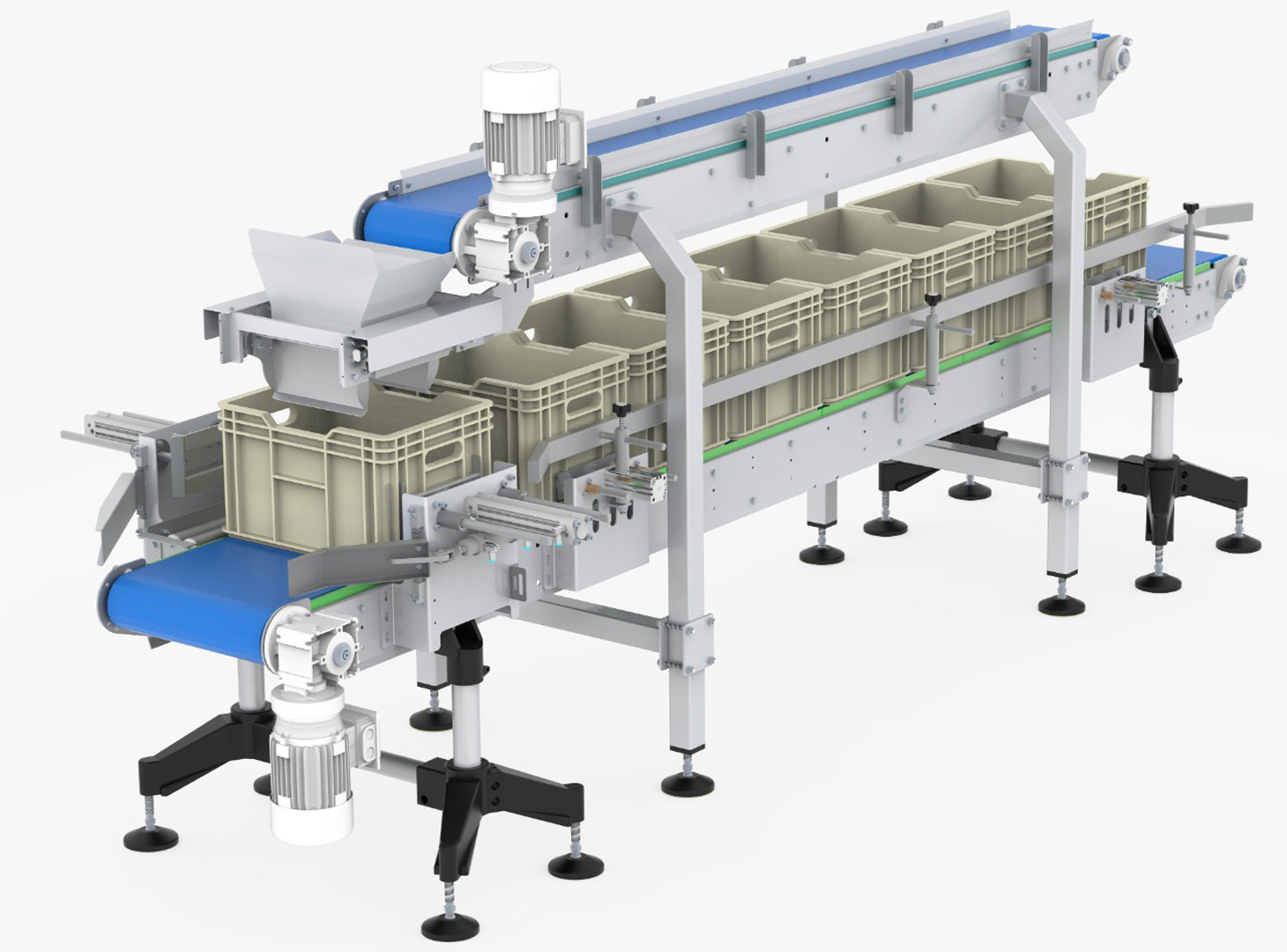

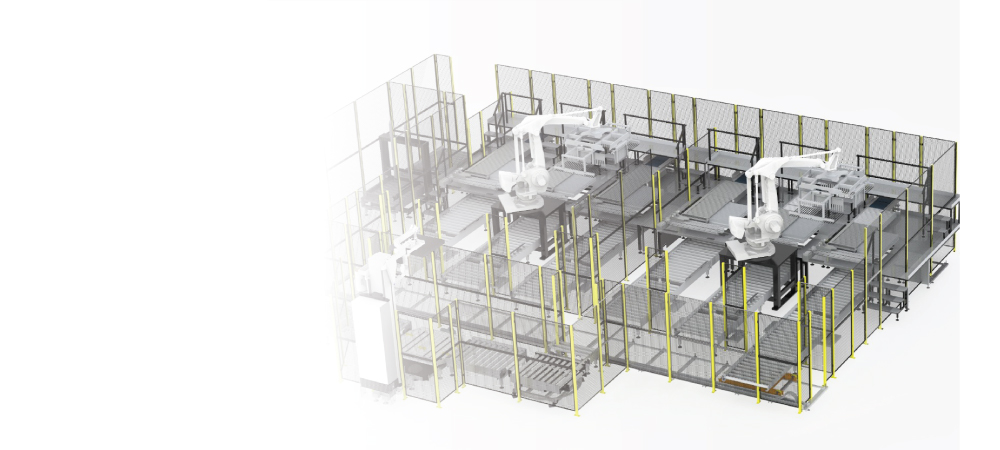

The palletizing system with robotic arm, present in different industrial sectors, is integrated into end-of-line systems with the ability to work several production lines simultaneously. This technology allows you to manipulate, with the same robot, lines with small formats or at a full level. At the same time, offering configurable capacities according to the production processes of each plant.

Main benefits

- It is practical and fast because its installation is designed and manufactured for palletizing and palletizing the finished product, delivering direct stowages for commercialization.

- Its design is designed for the characteristics and type of product of its destination.

- The equipment is programmed to work autonomously.

- The system is equipped with security elements that protect the operator in the event of unauthorized access to an internal operating area of the system.

Plus differential of the palletizing with robotic arm

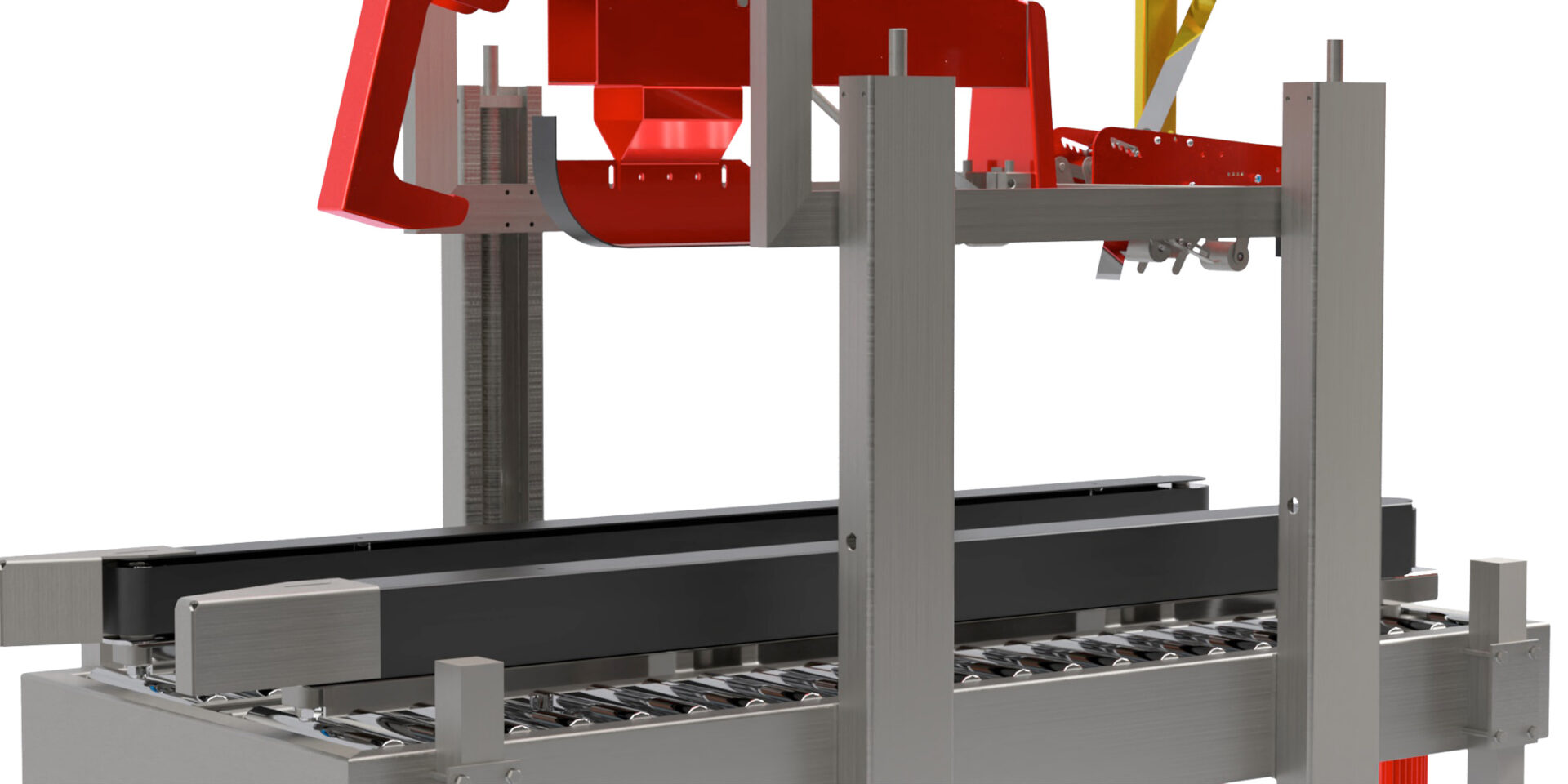

- The palletizing cell is designed to palletize and enfarte the product, delivering stowages directly for storage or distribution.

- Each robotic arm can handle up to three independent supply lines of products to be palletized.

- The design of the claw or influenzar is made according to your product or need and can include different technologies for its operation.

Expected metrics and outstanding indicators from the team

Its capacity design is proportional to the quantities of production. A palletizing system with a robotic arm can handle finishing speeds of up to 30 stowages per hour.

Manufacturing details

The equipment is made of 304 stainless steel, steel zincado And carbon steel with electrostatic paint finish with RAL palette color at the customer’s selection and other engineering materials; including plastics and specialized compounds, suitable for contact with food that guarantee process hygiene and a long service life of the equipment

Aspects of maintenance

All ESSI end-of-line equipment are highly functional systems that require a control and maintenance scheme to guarantee and ensure indicators of reliability, availability and production performance.

ESSI has a portfolio of services and spare parts for the timely realization of preventive and corrective maintenance. It also offers a timely remote and face-to-face technical assistance system at all times.