Pick and Place

- Home

- soluciones

- End of line

- Pick and Place

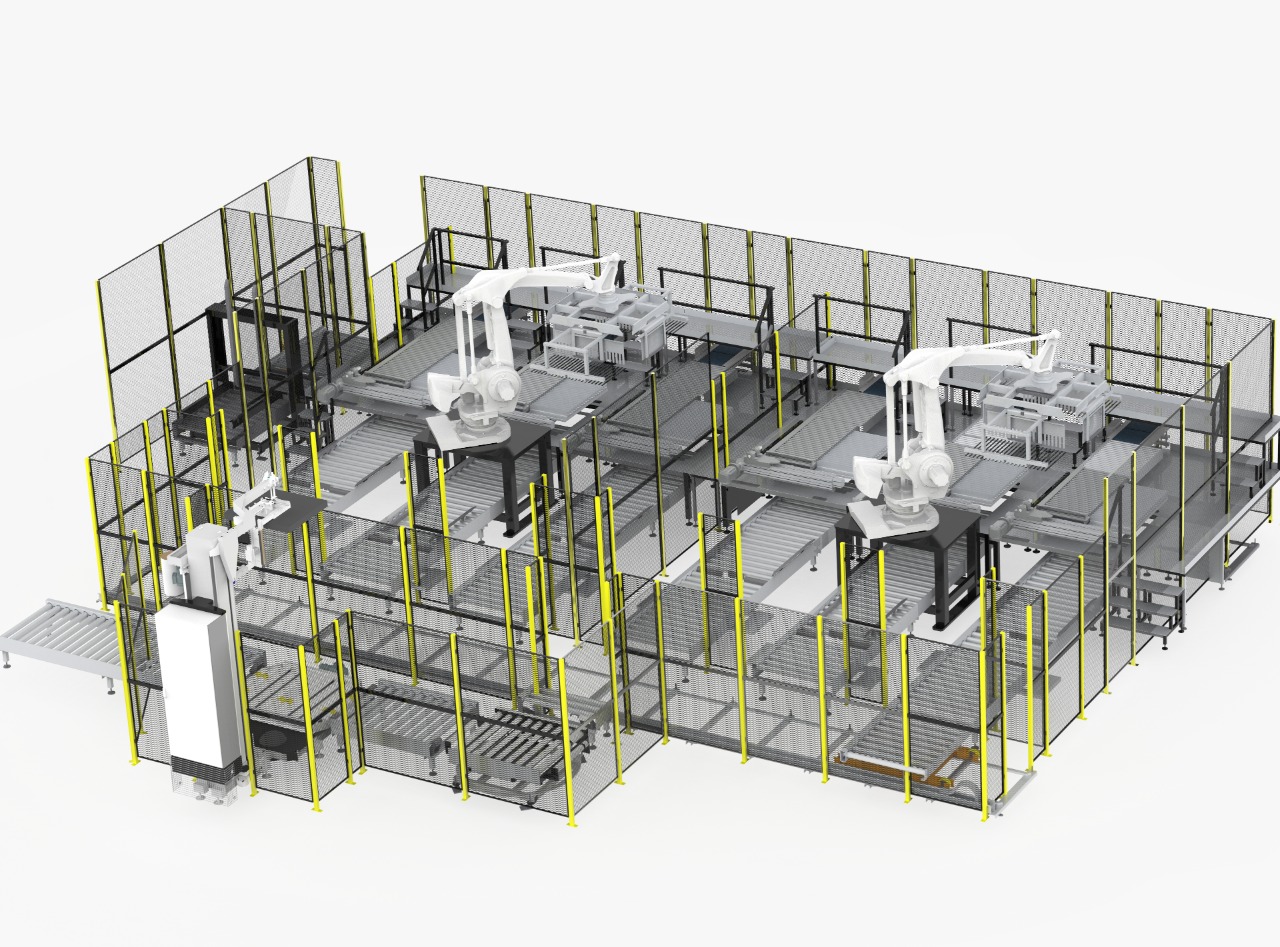

End of line

Pick and Place

Custom-made design.

Technical characteristics

Most relevant features

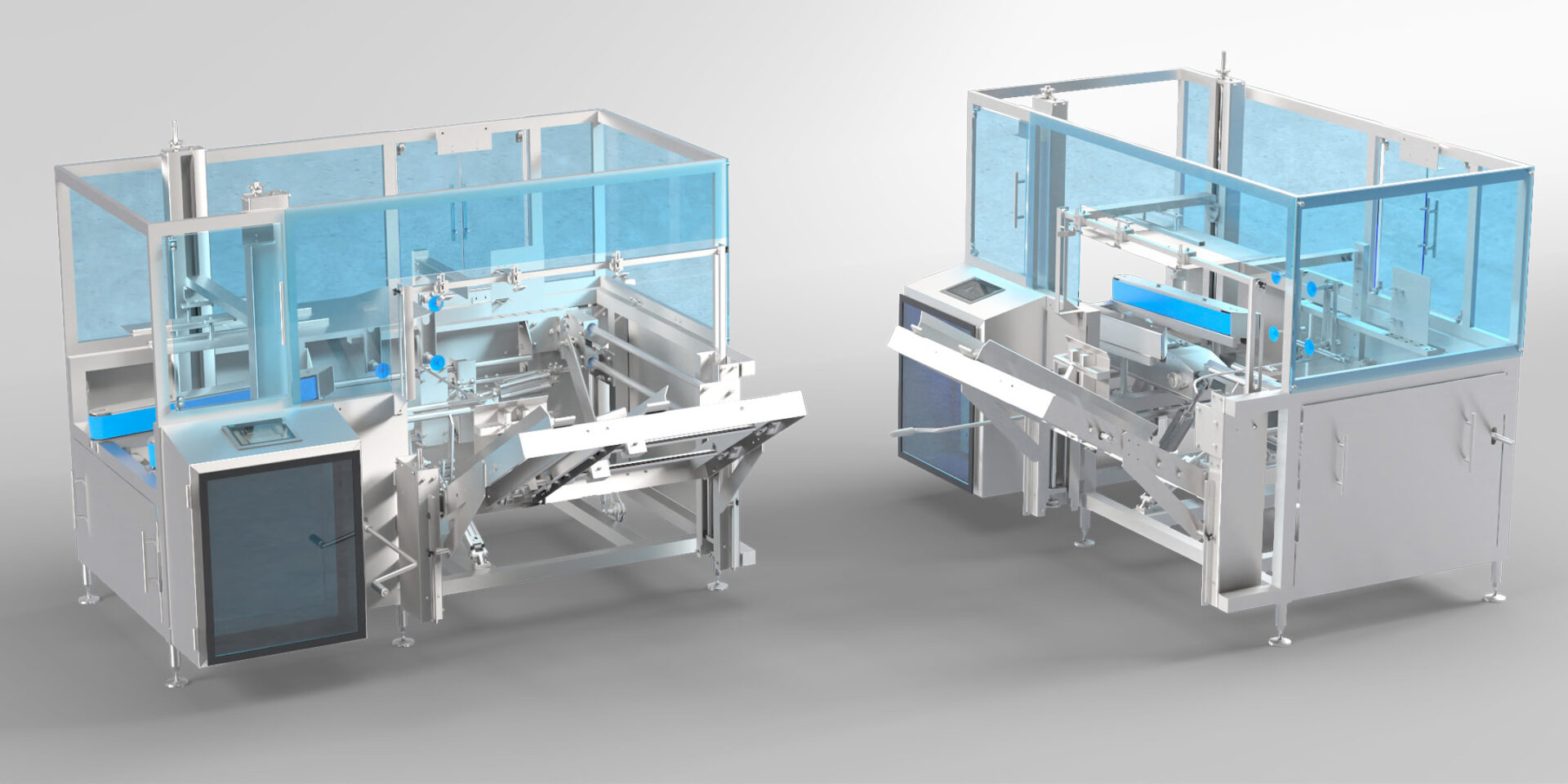

The Pick and Place equipment, with a large flexible product, is a machine made up of automatic systems that guarantee the smooth, fast and controlled handling of the product. The design of the suction cup in conjunction with the pneumatic Bagger system guarantees the fastening, transfer and arrangement of the product. Además, la estructura rígida y modular, permite el correcto posicionamiento de los sistemas móviles y manipuladores del producto.

Likewise, it guarantees savings in industrial services, since the generation of vacuum is carried out through an efficient and innovative system, which allows energy consumption only when required; contributing to energy savings and care for the environment.

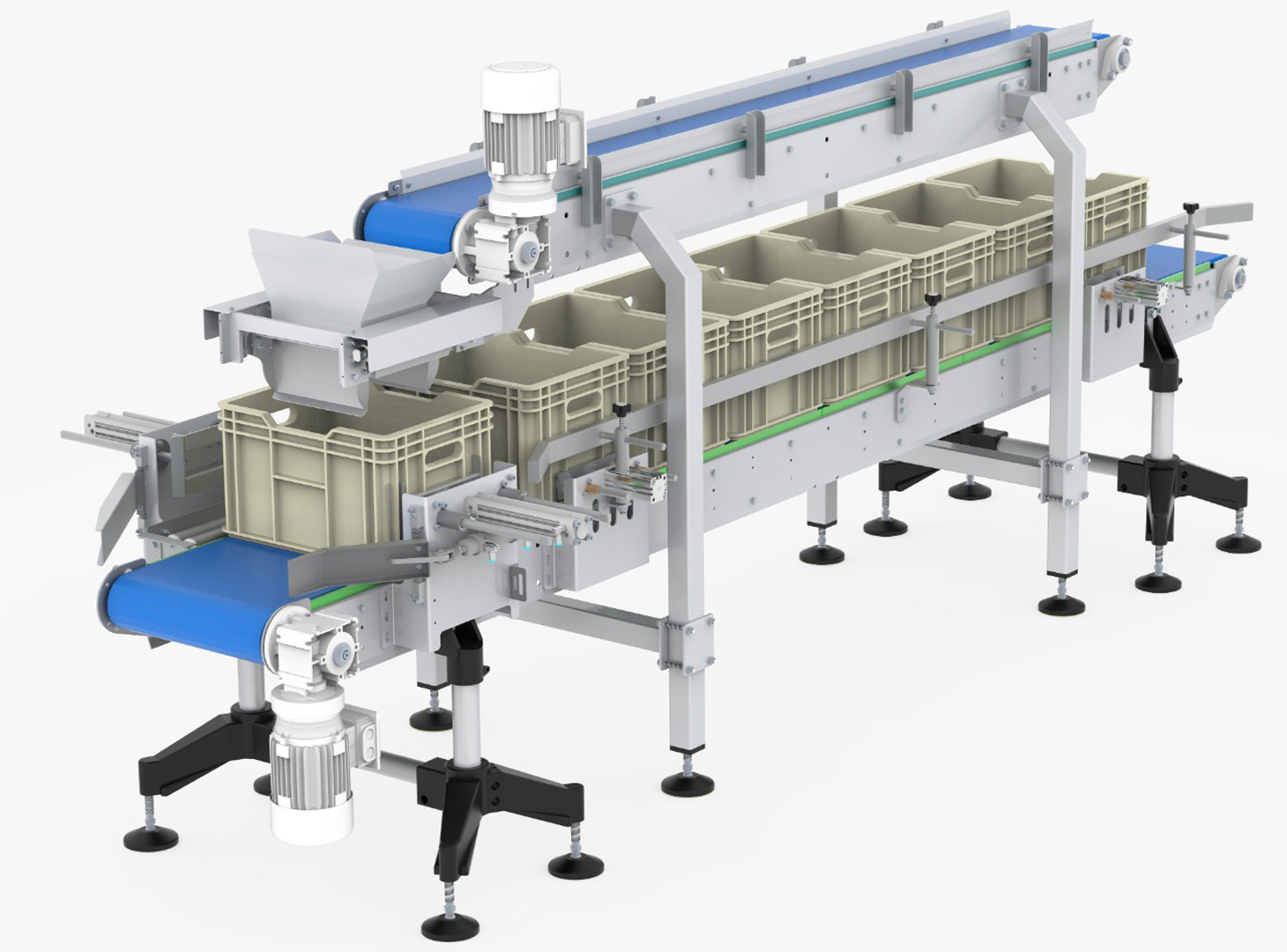

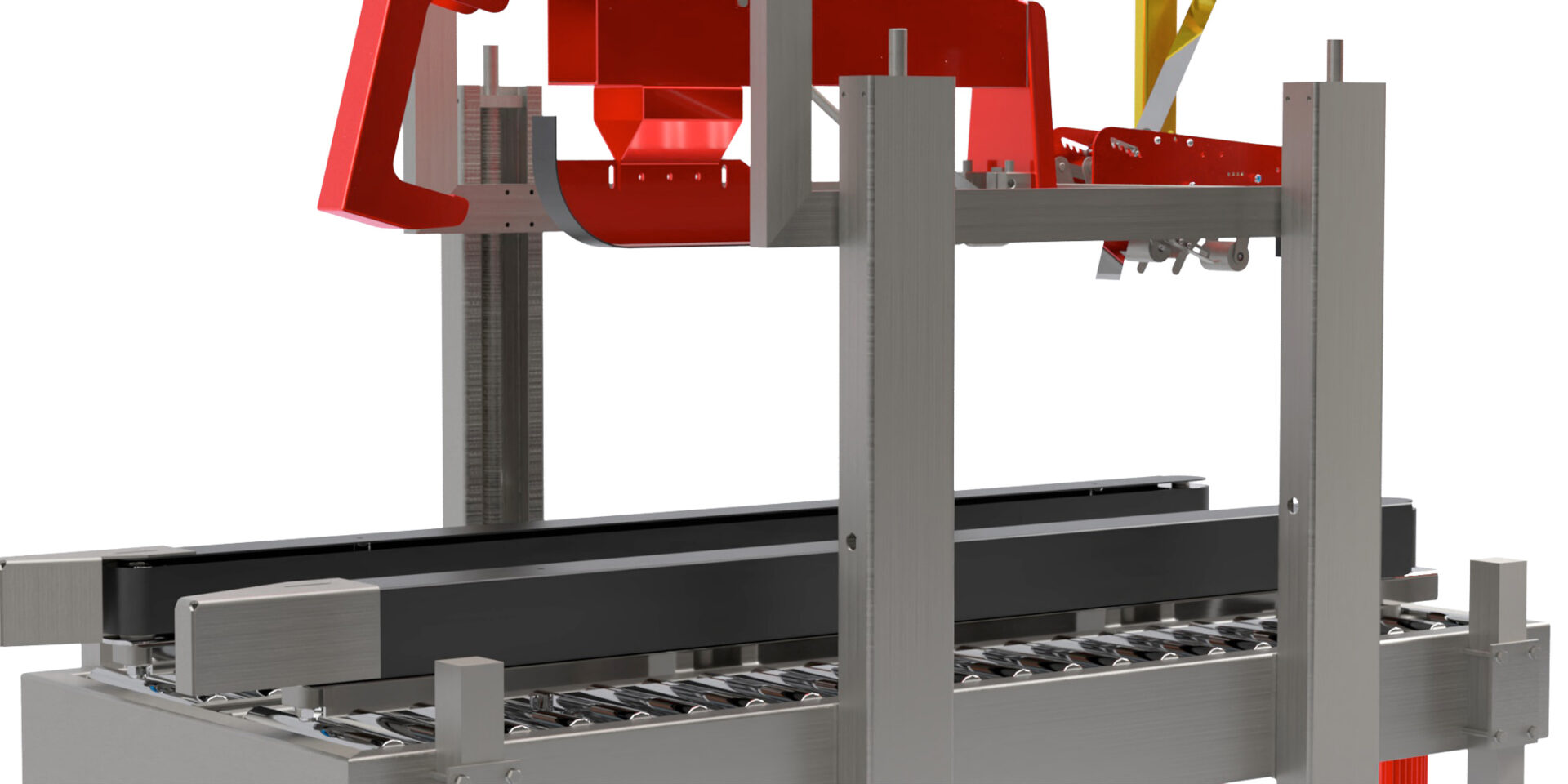

This innovative solution has been designed for the repackaging of buckets or boxes with the following design characteristics:

- Making product counts up to 9,000 u/h.

- Counting and location of the product in a band with unique spaces designed for the accommodation and protection of the product.

- Vacuum suction cup product grip systems, designed to take the product efficiently without leaving marks or mistreating the packaging.

Main benefits

- Pick and Place equipment for handling products in ranges from 900 ml to 2,500 ml.

- Repack in an orderly way in a cardboard box and buckets, ensuring the location and protection of the product in the transport process.

- Productive support for long hours of work, improving process efficiencies in relation to manual packaging.

- Count of high-precision units according to the standard of units in the box requested by the customer.

Plus spread of the Pick and Place

- The Pick and Place team has a system specialized in the handling of liquid products in plastic bags or flexible packaging.

- It also has a recipe handling of different presentations of large products from 900 ml to 2,500 ml.

- Place the products or bags in the boxes or buckets in an orderly manner, ensuring the best location.

- Controlled management from a plastic bucket or cardboard box, which allows you to operate with the two containers independently and make changes to the transport units, or bands quickly.

Expected metrics and indicators

- Effective handling of products from 900 to 2,500 ml in a flexible plastic bag.

- It reaches a product handling speed of up to 9,000 u/h depending on the presentation and size of the product.

- Manage buckets or cardboard boxes up to 1,080 u/h.

Manufacturing details

The Pick and Place equipment is made of 304 stainless steel and other engineering materials, including specialized plastics and compounds, suitable for contact with food in order to guarantee the hygiene of the process and a long service life of the equipment..

Aspects of maintenance

All ESSI End of Line teams are highly functional systems that require a control and maintenance scheme to guarantee and ensure indicators of reliability, availability and production performance.

ESSI has a portfolio of services and spare parts for the timely realization of preventive and corrective maintenance. It also offers a timely remote and face-to-face technical assistance system at all times..