UHT Sterilizer

- Home

- soluciones

- Process

- UHT Sterilizer

Process

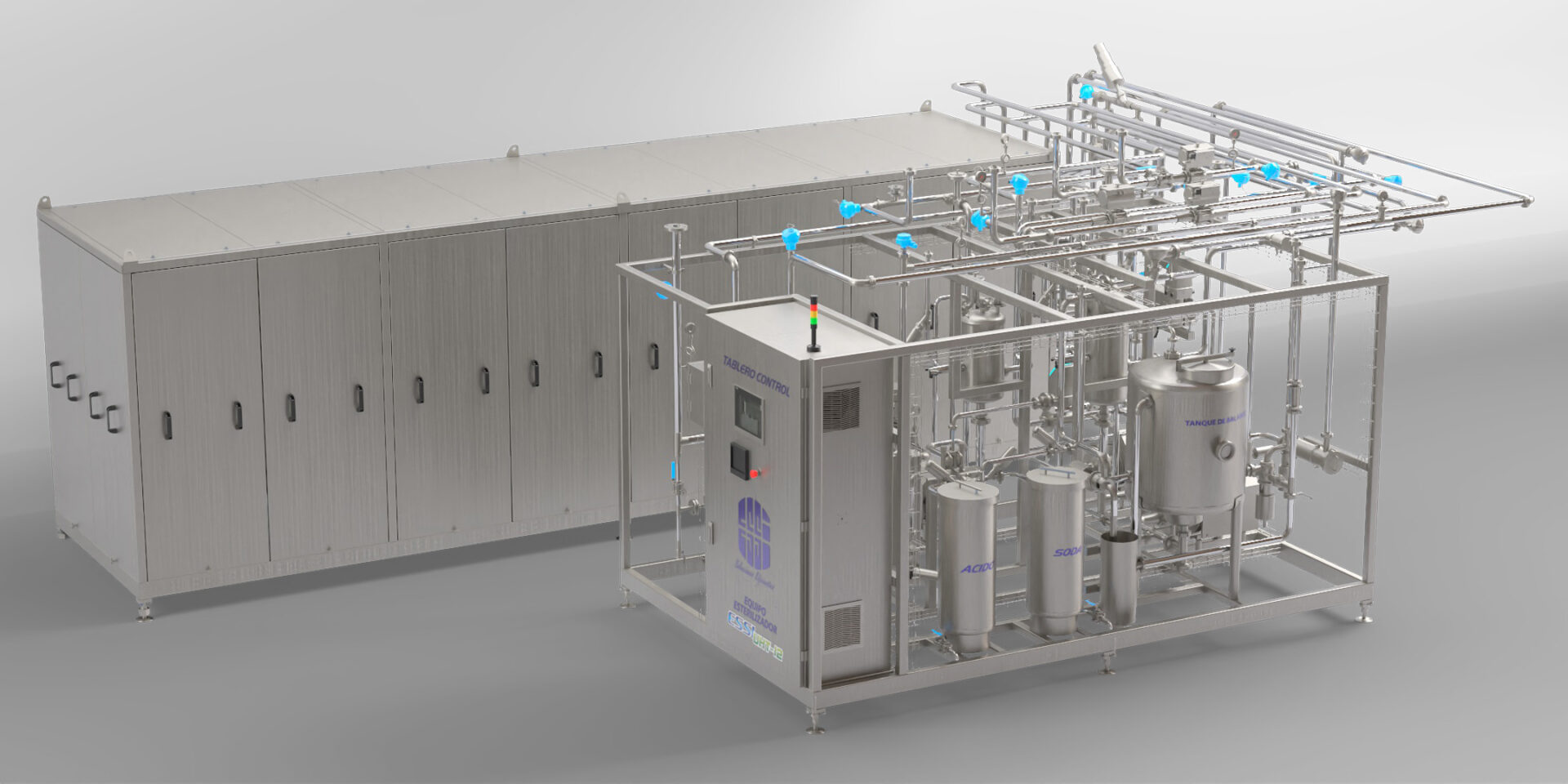

UHT Sterilizer

Technical characteristics of the equipment

The ESSI UHT Sterilizer allows the production of long-lived food liquids with high energy efficiency, reducing the mistreatment of the product. This sterilization unit is designed for the heat treatment of milk and its derivatives or other food products such as soft drinks..

With its automatic controls, the equipment guarantees operation with the intervention of an operator, since it performs its washing cycles, temperature control and production automatically; guaranteeing the quality of the product. Due to its modular manufacture, the equipment adapts to the different requirements of the customer.

ESSI manufactures models between 3,000 and 25,000 L/h based on the following parameters:

- Cost.

- Technology.

- Service consumption vs. capacity.

- Dimensions:.

This allows the installation of equipment with a long service life, which leads to low maintenance costs.

Most relevant features

- The equipment is designed for the production of UHT food liquids.

- Due to its high performance and high heat exchange efficiency, its continuous operation is guaranteed for long production periods.

- Energy optimization thanks to calenders made of spiral tubes.

Main benefits of the UHT Sterilizer

- Advanced system in CNC design, calculation, modeling and machining software that allows you to optimize and control processes in a fully automated way.

- Optimization of chemical inputs and water.

- Temperatures in the homogenizer of up to 90°C that prevent the deterioration of the pistons and packaging.

- Pumps with state-of-the-art engines that guarantee 93% energy efficiency.

- Variable flow depending on the consumption of the packaging machines.

- Product return <=5%.

- SMS connections or maximum security flanges for interconnection of calender and pipes.

- Remote assistance.

- Simplicity in the handling and learning of automated systems.

Expected metrics and highlights of the team

- Registration of the critical control point.

- Protein stabilization temperature control.

- Historical record of alarms.

Manufacturing details

- Parts in contact with the product: AISI 316L.

- Structure: AISI 304.

Aspects of maintenance

All ESSI process teams are highly functional systems that require a control and maintenance scheme to ensure the assurance of reliability, availability and production performance indicators.

In this way, ESSI has a portfolio of services and spare parts for the timely performance of preventive and corrective maintenance, offering a timely remote and face-to-face technical assistance system at all times.