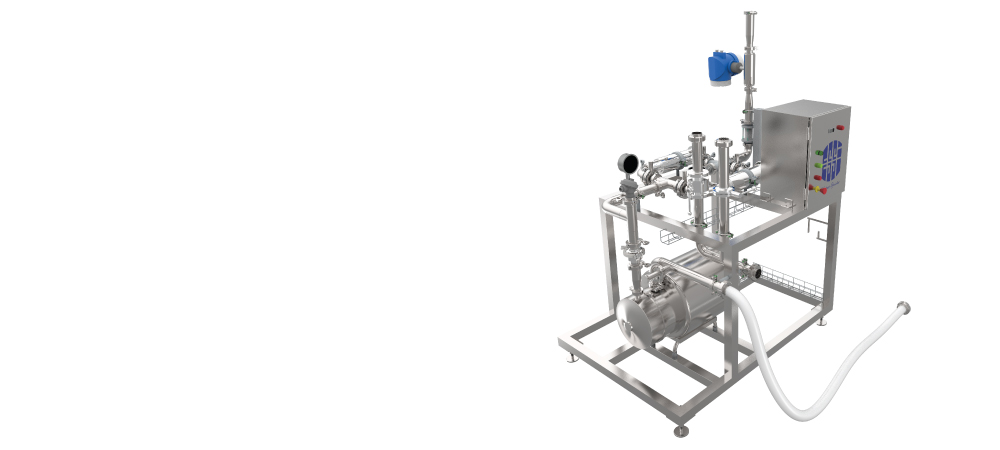

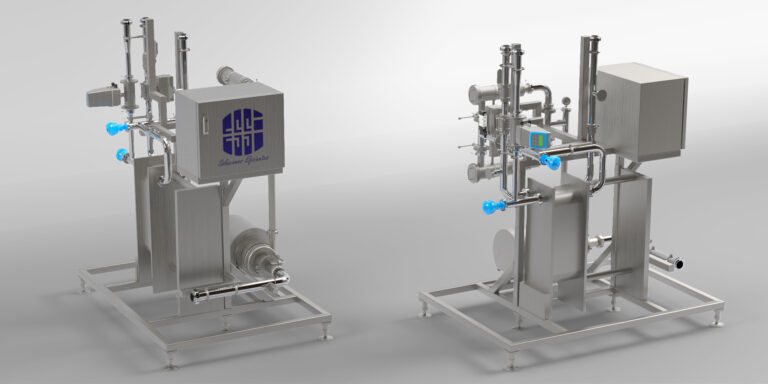

Receipt Skid with Exchanger

- Home

- soluciones

- Process

- Receipt Skid with Exchanger

Process

Receipt Skid with Exchanger

Technical characteristics of the equipment

Hygiene is a fundamental principle in food processes, implementing controls for the management of microorganisms and enzymes during the collection and reception of milk directly influences the quality of the final product..

The Receipt Skid with Exchanger is a system designed to continue guaranteeing product quality through the unloading, sampling, analysis, maintenance of the cold chain and filtering of raw milk from milking farms. Its production volume is 10,000 to 25,000 L/h and the filtering systems have independent operation.

The Assembly of the Receipt Skid with Exchanger is installed in a compact structure, designed to facilitate its packaging, transport and location. This structure maintains enough internal space that allows the maneuverability required by the operator for the maintenance work or handling of any of the installed lines.

Most relevant features

- It allows the collection of samples.

- Sense of temperature, pressure and flow in line.

- Parallel filter battery.

Main benefits of the Receipt Skid with Exchanger

- Advanced system in CNC design, calculation, modeling and machining software that allow you to optimize and control processes in a fully automated way.

- Cleaning the sieve without disassembling or disassembling the filter.

- AISI 316L stainless steel plate exchanger with NBR gaskets, according to the customer's and process requirements.

- SMS connections or maximum security flanges for interconnection of circuits.

- Integrated pumping, measurement, filtration and cooling solution.

Expected metrics and outstanding indicators from the team

- Product input and output temperature.

- Volume received by each supplier.

- Total volume received.

Manufacturing details

The entire receipt set is designed for a hygienic environment and is entirely made of 304 stainless steel, even some components are made of 316L stainless steel. Your SMS boards are aimed at maintaining the hygiene of the download process. In addition, its design has been designed so that the assembly to the final product line is quite practical.

Aspects of maintenance

All ESSI process equipment, such as the Receipt Skid with Exchanger, are highly functional systems that require a control and maintenance scheme to ensure the assurance of reliability, availability and performance indicators in production.

In this way, ESSI has a portfolio of services and spare parts for the timely performance of preventive and corrective maintenance, offering a timely remote and face-to-face technical assistance system at all times.